News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

The TRICONEX 8312 is a high-performance, programmable, scalable safety instrumentation system input/output module with multiple redundant designs, 8 channels, analog and digital input/output support, and rich communication interfaces for industrial automation, petrochemical, natural gas and other industrial sectors

Here is a detailed description of the TRICONEX 8312 input/output module:

Processor: The 32-bit RISC microprocessor provides fast and reliable decision-making and control capabilities.

Memory: Equipped with 8MB RAM and 64MB flash.

Input/output: up to 384 digital input/output, 64 analog input/output, 8 channels, support analog and digital input and output, can be connected to temperature, pressure, liquid level and other sensors to monitor process variables and achieve control of the production process.

Communication interface: There are 1 Ethernet port and 2 serial ports, supporting Ethernet, RS-232, RS-485 and other communication interfaces, to facilitate communication and data exchange with other control equipment, PLC or host computer.

Power supply: 24V DC power input.

Operating temperature: 0℃ to 60℃.

Dimensions: 4.4 inches x 12.4 inches x 10.3 inches.

Features: In line with SIL 3 certification, with high safety; Multiple redundancy design, enhance the fault tolerance of the system, automatically switch to the backup channel when failure occurs; Modular design, easy to install, maintain and expand; With status monitoring and alarm function, can detect and respond to system anomalies in time; Module design efficient, reduce power consumption and heat, suitable for long-term stable operation, can adapt to a wide range of industrial environment temperature, high protection level, suitable for harsh industrial environment.

Applications: Suitable for petrochemical, natural gas processing, power, pharmaceutical and other industrial fields, as well as other occasions with high safety and reliability requirements, to provide strong support for industrial automation and safety-critical applications.

TRICONEX 8312 Input/output module More products Click [TRICONEX]

Triconex Main Products

Triconex CPU:3006、3007、3008

Digital Input Module:3501E、3502E、3503E、3504E、3505E、3564

Analog Input Module:3721、3700、3701、3703E、3704、3708E

Pulse Input Module:3510、3511、3515

Thermocouple Input Module:3706A

Digital Input Module:3664、3674

SDO:3613E、3611、3614E、3615E、3617E

16 point:3624、3623

Analog Onput Module 3805E

Triconex Tricon Communication Module TCM 4351B

Intelligent Communication Module 4119 4119A

Network Communication Module 4329

Termination Board:9753-110、9662-610、9563-810、9760-210、9662-110

Cable:4000094-310、4000094-320、4000093-320、4000093-310 4000098-510、4000103-520

Description

The Triconex Enhanced Diagnostic Monitor software program monitors the hardware,communication,and application health and status of Triconex controllers.It provides easy diagnostics for status and fault analysis.Information is automatically available in the diagnostic monitor for quick and easy analysis—no special training is required.New features of the latest Enhanced Diagnostic Monitor include:

•New updated GUI supporting the use of NAMUR 107 symbology to provide greater detail and visual awareness.•Addition of new reports to view node status.

•Support for Tricon system version 11.2.

•Improved event collection performance.

•Support for periodic data collection.

•Ability to view events offline without connecting to a node.

•Improved,easier-to-use interface for viewing and sorting events.The Triconex Sequence of Event Recorder software application retrieves the detailed SOE data from the Triconex controllers for display and analysis.New features of the latest SOE application include:

•Support for Tricon system version 11.2.

•Support for an increased number of tagnames with a corresponding increase in bin sizes in Tricon 11.2 and later systems with only TCMs installed.

•The maximum number of tagnames is now approximately 29,000(previous versions supported a maximum of approximately 13,000 tagnames).

Tricon CX Safety platform The latest Triconex Safety Integrity Level(SIL)3 safety system that leverages the best of the proven Tricon and Trident platforms in a new compact form factor together with enhanced functionality that delivers safety for life.

Online upgrade starts here The latest release of the Tricon Main Processor module(3009)now provides the ability to upgrade from a Tricon 10.3,10.4,or 10.5 system with 3008 Main Processors to a Tricon 11.2 system with model 3009 Main Processors,while the system is online

Triconex Main Products

Triconex CPU:3006、3007、3008

Digital Input Module:3501E、3502E、3503E、3504E、3505E、3564

Analog Input Module:3721、3700、3701、3703E、3704、3708E

Pulse Input Module:3510、3511、3515

Thermocouple Input Module:3706A

Digital Input Module:3664、3674

SDO:3613E、3611、3614E、3615E、3617E

16 point:3624、3623

Analog Onput Module 3805E

Triconex Tricon Communication Module TCM 4351B

Intelligent Communication Module 4119 4119A

Network Communication Module 4329

Termination Board:9753-110、9662-610、9563-810、9760-210、9662-110

Cable:4000094-310、4000094-320、4000093-320、4000093-310 4000098-510、4000103-520

Manufacturer:Triconex

Product No.:3700A

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

Why are the prices of many products of our company more competitive?

(1)Source purchase to reduce the price difference in the intermediate phase

(2)Stable channel and more guaranteed supply

Lead time problem

(1)For the spot products in stock,the delivery can be arranged on the same day after the contract payment is signed

(2)Order products and deliver according to the quoted delivery date

The following are our company's superior products(most of which are used daily)and the ones that are not commonly used are not listed,but all of which have been done.Welcome to your consultation!

→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→→

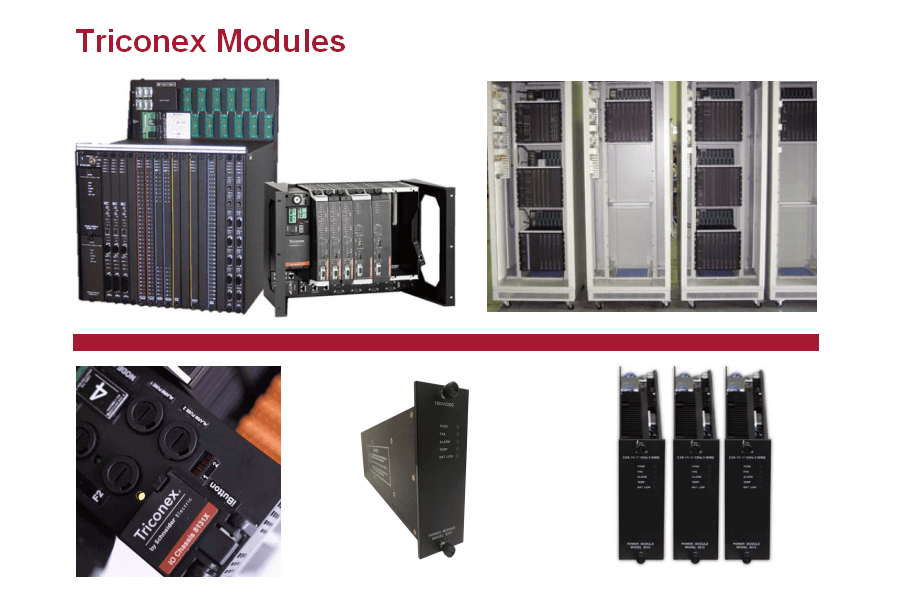

The Triconex system usually consists of the following typical modules:

Main Processor modules (triple).

Communication module(s) .

Input and output modules: can be analog and/or digital and work singular or in hot-spare (standby).

Power supply modules (redundant).

Backplane(s) (chassis) that can hold the previous modules.

System cabinet(s): can compact one or more chassis in one cabinet.

Marshalling cabinets to adapt and standardize interface connections between the field instruments and the Triconex system cabinets.

Human machine interface (HMI) to monitor the events.

Engineering workstation (EWS) for programming. monitoring, troubleshooting and updating.

The Triconex main processors can communicate with the so-called TriStation 1131 application software to download, update and/or monitor programs. These programs are either written in:

Function Block Diagram language,

Ladder diagram language, or

Structured text (Pascal like) Language.

Cause and Effect Matrix Programmable Language (CEMPLE).

Besides, a Sequence of Events (SOE) recorder software and Diagnostic monitor software are implemented.

Industries

Refining and petrochemicals

Upstream and midstream oil and gas

Chemicals and specialty chemical

Power generation

Pharmaceuticals

Safety and critical control applications

TÜV-certified for SIL 3 applications to international standard IEC61508: 2010

– Emergency shutdown systems (ESD control)

– Fire and gas systems (F&G control)

– Burner management systems (BMS controls)

– High-integrity pressure protection systems (HIPPS control)

– Turbomachinery control (TMC) and protection systems

Works in both centralized plus distributed and remote I/O applications

Suitable for use in harsh environments