News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

The GE Hydran 201Ti is a continuous dissolved gas in oil analysis (DGA) monitor designed to provide early warning of transformer failure conditions, thereby minimizing unplanned power outages. Here is a detailed description of the product:

Product overview

Application: Used to monitor dissolved gas in transformer oil and provide early fault warning.

Features: Small, easy to install, provides single-fault gas composite readings (ppm), and local and remote alarm functions.

Technical specification

sensor:

The composite gas sensor is 100% responsive to hydrogen (a common fault gas) and is sensitive to gases such as carbon monoxide (overheated paper), acetylene (electric arc) and ethylene (overheated oil).

Optional "Hydrogen Only" sensor that focuses only on hydrogen production.

Power source:

Includes a power supply that can accommodate 115/230V AC, 50/60Hz single-phase (factory setting), with a maximum rated power of 475VA.

Measuring range:

The gas concentration measurement range is usually 0-2000 ppm (volume ratio, with hydrogen as the equivalent).

Measurement accuracy:

±10% reading ±25 ppm (H2 equivalent).

Communication interface:

RS-485 (Terminal block), isolated to 2000 Vac RMS, supports Modbus or Hydran protocols for remote communication.

USB port (Type B connector) for local connection to laptop for system configuration.

Function and advantage

Continuous monitoring: Real-time measurement of critical fault gases to provide insight into the condition of the transformer.

Alarm setting:Two alarm levels (alarm and alarm) can be configured to indicate an increase in severity.

Alarms can be set according to the gas ppm level or gas change rate (hourly or daily).

Remote monitoring: Remote transmission of gas ppm values and gas change rate values to avoid site visits.

Self-check and self-diagnosis: Automatic self-check every 15 days, triggering a service alarm when a fault is detected.

Easy to install and maintain:

Permanently installed on a single transformer oil valve, no additional piping or pumps required.

No field calibration required.

Application field

Power Utilities: For simple and effective non-critical transformer solutions that centralize and prioritize asset replacement strategies.

Industrial plants: Reduce the risk of process disruptions due to power outages and minimize costly downtime.

Sum up

GE Hydran 201Ti, a continuous dissolved gas analysis monitor in oil, is an important tool for transformer failure warning due to its small size, easy installation, high sensitivity and remote monitoring. By monitoring dissolved gas in oil in real time, it provides workers with early warning of failures, helping to reduce the risk of unplanned outages and improve the reliability and stability of the grid.

After sales guarantee

1. Enjoy a one-year warranty

2. Enjoy new discounts

3. For any hesitation, contact us to obtain certification

4. Enjoy fast delivery and transportation, usually taking 3-5 days

5. Payment terms: 100% wire transfer before shipment

The original packaging and large inventory will be shipped as soon as possible by FedEx, SF Express, Debon Express, and JD Express!

The following are our company's main products. For more products, please consult our sales manager

Contact person: Li Ming

Email: plc66@qq.com

WhatsApp:+8618059884790

WeChat: 18059884790

Contact phone number:+8618059884790

Address: Unit 2010, No.1733 Lvling Road, Siming District, Xiamen City, Fujian Province, China

Why are many of our products more favorably priced?

(1) Source procurement, reduce the intermediate link price difference

(2) The channel is stable and the supply of goods is more secure

Delivery problem

(1) Stock spot products, after signing the contract payment, you can arrange delivery on the same day

(2) The ordered products shall be delivered according to the quoted delivery time

Company adhering to the "spare parts supply chain to enhance the value of" enterprise philosophy,

Our advantage is: new original, provide one-year warranty after sale! All products of the company have been strictly tested, welcome inquiry, acquisition. As long as you are sincere,

The company will provide you with a price advantage over peers, and win the list together!

ABB's global business is divided into four major business units, each consisting of specific business units focused on different industries and product categories

Model display

5SHY4045L0006,5SHY3545L0010,5SHX2645L0002

5SHY3545L0020,5SHY5045L0020,5SHY35L4520

PM904F,PM861AK01,PM866K01,PM864

PM864AK01,PM865K01,PM511V16,PPD113

PPD512,PFSK151,PFEA112-65,PFEA113-65

PFCL201C 10KN,PFTL101A 1.0KN,PFTL101B 5.0KN

GE is committed to continuous innovation, invention, and recreation, transforming creativity into leading products and services. G is composed of three major business groups: aviation, healthcare, and energy

Model display

IS200WETBH1ABA,IS210BPPBH2BMD,IS215UCVEH2AE

IS220PDOAH1A,IS420ESWBH3A,IS230SNIDH1A

DS200DCFBG1BLC,VMIVME-7750,VMIVME-7700

VMIVME-7658,VMIVME-4140,VMICPCI-7806

VMIVME-7807RC

The Bently 3500 series mechanical protection system, monitor, and Bently Nevada vibration sensor probe are well matched and have a wide measurement range, making it a Bently vibration monitoring product in the United States. It can be used for measuring shaft vibration, shaft displacement, key phase, speed, overspeed protection, eccentricity, thermal expansion, differential expansion, etc. It accepts vibration signals from bently3300 eddy current sensor systems (Bently3300XL sensor probes, extension cables, proximitors) as well as speed acceleration sensors such as 330500, 330400, 9200, etc. Meets the American Petroleum Institute 670 standard. The bently3500 system can monitor the vibration of large rotating machinery such as steam turbines, water turbines, fans, compressors, turbine expanders, electric motors and generators, exciters, gearboxes, water pumps, etc. Widely used in power plants, chemical plants, refineries, steel plants, machinery plants, water pump plants, fan plants, university research units, and complete automation instrument enterprises. The bently3500 framework instrument system mainly includes:

Bently 3500/05 System Framework: Model 14 module slots 3500/05-01-01-00-00-01; 7 slots 3500/05-02-04-00-00-01

Bently 3500/15 power supply (new): Model 3500/15-05-05-00 (front panel 106M1079-01, back panel 106M1081-01)

Bently 3500/20 Framework Interface Module

Bently3500/22M Framework Interface Module with TDI: Models 3500/22-01-01-00 (Front Panel 288055-01, Back Panel 146031-01)

Bently 3500/25 Keyphasor Module: Models 3500/25-01-01-00 (Front Panel 149369-01, Back Panel 125800-01)

Bently 3500/32 4-Channel Relay Module: Models 3500/32-01-00 (Front Panel 149986-02, Back Panel 125720-01)

Bently 3500/33 16 Channel Relay Module: Models 3500/33-01-00 (Front Panel 149986-01, Back Panel 149992-01)

Bently 3500/34 TMR Relay Module

Bently 3500/40M Proximitor displacement monitor: models 3500/40-01-00 (front panel 176449-01, back panel 125680-01)

Bently 3500/42M displacement/velocity acceleration monitoring: Model 3500/42-01-00 (front panel 176449-02, back panel 128229-01)

Bently 3500/44M aerodynamic monitor

Bently 3500/45 Differential Expansion/Axial Position Monitor: Model 3500/45-01-00 (Front Panel 176449-04, Back Panel 135137-01)

Bently 3500/46M Hydroelectric Monitor

Bently 3500/50 Speed Module: Models 3500/50-01-00-01 (Front Panel 288062-02, Back Panel 133442-01)

Bently 3500/53 overspeed detection module

Bently 3500/60 and 3500/61 temperature monitors: models 3500/60-01-00 (front panel 163179-01, back panel 133819-01); 3500/61-01-00 (163179-02133819-02)

Bently 3500/62 Process Variable Monitor: Model 3500/65-01-00 (Front Panel 14598802, Back Panel 17210301)

Bently 3500/64M dynamic pressure monitor

Bently 3500/72M piston rod position monitor

Bently 3500/77M cylinder pressure monitor

Bently 3500/90 Communication Gateway

Bently 3500/92 Communication Gateway: Models 3500/92-01-01-00 (136180-01125736-01) and 3500/92-02-01-00 (136180-01133323-01)

Bently3500/01-01 Configuration Software

Bently 3500/06 protective box

Bently 3500/08 Fault Diagnosis Connection Panel

Bently 3500 Internal Safety Barrier: Model 3500/04 (136719-01138257-01)

Bently 3500/93 independent display device

Bently 3500/93 LCD display device

Bently 3500/94 VGA display device

Bently 3500/95 User Interface Workstation

The EcoStruxure Triconex Security System is an essential component of the EcoStruxure Plant, which is an enabling architecture for Schneider Electric's open IoT that provides operational business insights. With over 30 years of continuous secure operation, the EcoStruxure Triconex security system has achieved over one billion secure operating hours.

The advanced high availability and high integrity system series (Tricon, Tricon CX, Trident, and Tri-GP) have been certified by T Ü V Rheinland as Security Integrity Level 3 (SIL3) and can be used in all security and critical control applications. Verified in highly demanding industries and challenging applications, the EcoStruxure Triconex security system can provide high performance throughout its entire lifecycle.

Model display

Chassis:TRICONEX8110、TRICONEX8111、TRICONEX8112

Main processor module:TRICONEX3006、TRICONEX3007、TRICONEX3008、TRICONEX3009

Power Module:TRICONEX8310、TRICONEX8311、TRICONEX8312

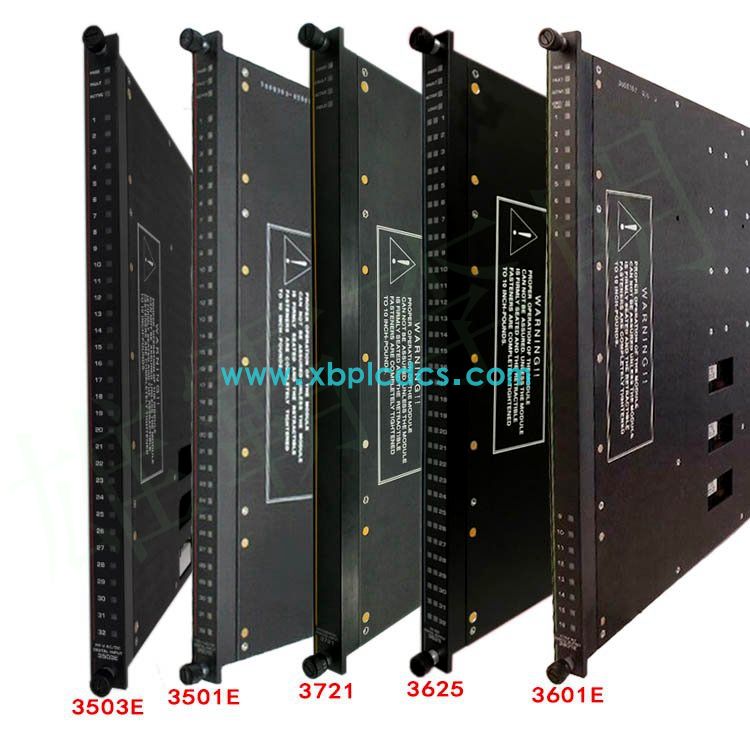

TMR Digital input module:TRICONEX3501E、TRICONEX3502E,TRICONEX3503E、TRICONEX3504E,TRICONEX3505E、TRICONEX3564、TRICONEX3506X

TMR Pulse Input Module:TRICONEX3510、TRICONEX3511

TMR Analog Input Module:TRICONEX3700、TRICONEX3700A、TRICONEX3701,TRICONEX3708E、TRICONEX3721、TRICONEX3720,TRICONEX3703E、TRICONEX3704E、TRICONEX3706E

Communication Module:TRICONEX4351B、TRICONEX4119,TRICONEX4509、TRICONEX4609、TRICONEX4429,TRICONEX4329、TRICONEX4352A、TRICONEX4409

TMR Digital Output Module:TRICONEX3624、TRICONEXV3625、TRICONEX3627,TRICONEX3627、TRICONEX3614E、TRICONEX3623,TRICONEX3664、TRICONEX3667、TRICONEX3636R,TRICONEX3607E、V3608E、TRICONEX3611E,TRICONEX3615E、TRICONEX3613E、TRICONEX3617E,TRICONEX3601E/T、TRICONEX3603E、TRICONEX3604E

Woodward is an independent designer, manufacturer and service provider of energy control and optimization solutions for aerospace and industrial markets. For 150 years, Woodward has focused its resources and expertise on delivering proven systems that perform under incredible demands. Our customers have come to rely on us to help them address and solve the challenges associated with global efficiency initiatives – from reducing emissions, to increasing energy efficiency, to helping them introduce alternative energy sources.

Model display

9907-164、9907-162、9907-149、9905-973

9907-165,9907-167,8440-2145,8406-113 ,8516-038

8446-1019,8237-1600,8200-1300,5501-471

5501-470,5501-467,5466-409,5466-316,5466-258