Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

ABB 5SHY35L4511 equipment specifications

I. Product overview

The ABB 5SHY35L4511 is a high-precision, high-performance industrial automation device or component from ABB. The device integrates ABB's advanced control technology and manufacturing processes to improve the operational efficiency and reliability of industrial automation systems. It is widely used in various industrial environments, such as manufacturing, automated production lines, robot systems, etc., to meet the needs of different industries for efficient and precise control.

Two, the main characteristics

High precision control:

The use of high-precision sensors and advanced control algorithms ensures that the equipment can achieve accurate control and adjustment during operation.

Meet the requirements of various complex processes for control accuracy, improve product quality and production efficiency.

Strong stability:

The use of high-quality materials and strict production process to ensure that the equipment has good stability and durability.

It can also maintain stable operation in harsh industrial environments, reducing failure rates and maintenance costs.

Easy to integrate:

Provides standard interfaces and communication protocols for easy integration with other devices and systems.

Simplify the process of system integration, reduce the difficulty and cost of system integration.

Intelligent management:

Supports remote monitoring and fault diagnosis. You can view device running status and parameters in real time over a network connection.

Provide intelligent early warning and alarm functions to discover and deal with potential problems in time to ensure production safety.

Third, installation and commissioning

Before installation:

Verify that the device model and specifications meet the requirements.

Check whether the appearance and package of the device are intact.

Prepare the tools and materials required for the installation.

Installation steps:

Install the device in the specified position according to the device layout diagram.

Connect all necessary cables and interfaces to ensure that the connections are secure and correct.

Secure the equipment to prevent movement or vibration during operation.

Debugging steps:

Before powering on, double check that all connections are correct.

Start the power supply, enter the debugging mode, and set parameters as required.

Observe the running status of the device and ensure that no abnormal alarm or fault occurs.

Carry out the necessary testing and calibration work to ensure that the equipment control accuracy and stability meet the requirements.

Fourth, maintenance and maintenance

Regular inspection:

Periodically check the appearance of the equipment and whether the connecting parts are in good condition.

Check whether cables and interfaces are loose or corroded.

Remove dust and dirt from the surface of the equipment.

Cleaning and maintenance:

Use a soft, dry cloth to wipe the surface of the device, avoiding chemical solvents or wet cloths.

Periodically check whether the cooling fan and air filter inside the device are clean and unblocked.

Troubleshooting:

If the device works abnormally or a fault alarm occurs, turn off the power and disconnect the device immediately.

Diagnose and rectify the fault according to the device manual or fault prompt.

If the problem cannot be resolved, contact ABB customer service or authorized distributor for technical support.

5. Precautions

Safe operation:

Before performing any operation, ensure that all power connections are disconnected and the relevant safe operation procedures are followed.

Avoid using equipment in humid, high temperature, or corrosive environments.

Environmental requirements:

The device must be installed in an environment with good ventilation, no dust, and no corrosive gases.

Avoid strong mechanical shock or vibration.

Storage and Transportation:

During storage and transportation, keep the device dry and clean, and avoid being squeezed or dropped.

Store the device in an environment with proper temperature and no corrosive gases.

After sales guarantee

1. Enjoy a one-year warranty

2. Enjoy new discounts

3. For any hesitation, contact us to obtain certification

4. Enjoy fast delivery and transportation, usually taking 3-5 days

5. Payment terms: 100% wire transfer before shipment

The original packaging and large inventory will be shipped as soon as possible by FedEx, SF Express, Debon Express, and JD Express!

The following are our company's main products. For more products, please consult our sales manager

Xiamen Xiongba E-commerce Co., Ltd

Contact person: Li Ming

Email: plc66@qq.com

WhatsApp:+8618046320074 (commonly used)

WhatsApp:+8618059884790

WeChat: 18059884790

Contact phone number:+8618059884790

Address: Unit 2010, No.1733 Lvling Road, Siming District, Xiamen City, Fujian Province, China

Why are many of our products more favorably priced?

(1) Source procurement, reduce the intermediate link price difference

(2) The channel is stable and the supply of goods is more secure

Delivery problem

(1) Stock spot products, after signing the contract payment, you can arrange delivery on the same day

(2) The ordered products shall be delivered according to the quoted delivery time

Company adhering to the "spare parts supply chain to enhance the value of" enterprise philosophy,

Our advantage is: new original, provide one-year warranty after sale! All products of the company have been strictly tested, welcome inquiry, acquisition. As long as you are sincere,

The company will provide you with a price advantage over peers, and win the list together!

ABB's global business is divided into four major business units, each consisting of specific business units focused on different industries and product categories

Model display

5SHY4045L0006,5SHY3545L0010,5SHX2645L0002

5SHY3545L0020,5SHY5045L0020,5SHY35L4520

PM904F,PM861AK01,PM866K01,PM864

PM864AK01,PM865K01,PM511V16,PPD113

PPD512,PFSK151,PFEA112-65,PFEA113-65

PFCL201C 10KN,PFTL101A 1.0KN,PFTL101B 5.0KN

GE is committed to continuous innovation, invention, and recreation, transforming creativity into leading products and services. G is composed of three major business groups: aviation, healthcare, and energy

Model display

IS200WETBH1ABA,IS210BPPBH2BMD,IS215UCVEH2AE

IS220PDOAH1A,IS420ESWBH3A,IS230SNIDH1A

DS200DCFBG1BLC,VMIVME-7750,VMIVME-7700

VMIVME-7658,VMIVME-4140,VMICPCI-7806

VMIVME-7807RC

The Bently 3500 series mechanical protection system, monitor, and Bently Nevada vibration sensor probe are well matched and have a wide measurement range, making it a Bently vibration monitoring product in the United States. It can be used for measuring shaft vibration, shaft displacement, key phase, speed, overspeed protection, eccentricity, thermal expansion, differential expansion, etc. It accepts vibration signals from bently3300 eddy current sensor systems (Bently3300XL sensor probes, extension cables, proximitors) as well as speed acceleration sensors such as 330500, 330400, 9200, etc. Meets the American Petroleum Institute 670 standard. The bently3500 system can monitor the vibration of large rotating machinery such as steam turbines, water turbines, fans, compressors, turbine expanders, electric motors and generators, exciters, gearboxes, water pumps, etc. Widely used in power plants, chemical plants, refineries, steel plants, machinery plants, water pump plants, fan plants, university research units, and complete automation instrument enterprises. The bently3500 framework instrument system mainly includes:

Bently 3500/05 System Framework: Model 14 module slots 3500/05-01-01-00-00-01; 7 slots 3500/05-02-04-00-00-01

Bently 3500/15 power supply (new): Model 3500/15-05-05-00 (front panel 106M1079-01, back panel 106M1081-01)

Bently 3500/20 Framework Interface Module

Bently3500/22M Framework Interface Module with TDI: Models 3500/22-01-01-00 (Front Panel 288055-01, Back Panel 146031-01)

Bently 3500/25 Keyphasor Module: Models 3500/25-01-01-00 (Front Panel 149369-01, Back Panel 125800-01)

Bently 3500/32 4-Channel Relay Module: Models 3500/32-01-00 (Front Panel 149986-02, Back Panel 125720-01)

Bently 3500/33 16 Channel Relay Module: Models 3500/33-01-00 (Front Panel 149986-01, Back Panel 149992-01)

Bently 3500/34 TMR Relay Module

Bently 3500/40M Proximitor displacement monitor: models 3500/40-01-00 (front panel 176449-01, back panel 125680-01)

Bently 3500/42M displacement/velocity acceleration monitoring: Model 3500/42-01-00 (front panel 176449-02, back panel 128229-01)

Bently 3500/44M aerodynamic monitor

Bently 3500/45 Differential Expansion/Axial Position Monitor: Model 3500/45-01-00 (Front Panel 176449-04, Back Panel 135137-01)

Bently 3500/46M Hydroelectric Monitor

Bently 3500/50 Speed Module: Models 3500/50-01-00-01 (Front Panel 288062-02, Back Panel 133442-01)

Bently 3500/53 overspeed detection module

Bently 3500/60 and 3500/61 temperature monitors: models 3500/60-01-00 (front panel 163179-01, back panel 133819-01); 3500/61-01-00 (163179-02133819-02)

Bently 3500/62 Process Variable Monitor: Model 3500/65-01-00 (Front Panel 14598802, Back Panel 17210301)

Bently 3500/64M dynamic pressure monitor

Bently 3500/72M piston rod position monitor

Bently 3500/77M cylinder pressure monitor

Bently 3500/90 Communication Gateway

Bently 3500/92 Communication Gateway: Models 3500/92-01-01-00 (136180-01125736-01) and 3500/92-02-01-00 (136180-01133323-01)

Bently3500/01-01 Configuration Software

Bently 3500/06 protective box

Bently 3500/08 Fault Diagnosis Connection Panel

Bently 3500 Internal Safety Barrier: Model 3500/04 (136719-01138257-01)

Bently 3500/93 independent display device

Bently 3500/93 LCD display device

Bently 3500/94 VGA display device

Bently 3500/95 User Interface Workstation

The EcoStruxure Triconex Security System is an essential component of the EcoStruxure Plant, which is an enabling architecture for Schneider Electric's open IoT that provides operational business insights. With over 30 years of continuous secure operation, the EcoStruxure Triconex security system has achieved over one billion secure operating hours.

The advanced high availability and high integrity system series (Tricon, Tricon CX, Trident, and Tri-GP) have been certified by T Ü V Rheinland as Security Integrity Level 3 (SIL3) and can be used in all security and critical control applications. Verified in highly demanding industries and challenging applications, the EcoStruxure Triconex security system can provide high performance throughout its entire lifecycle.

Model display

Chassis:TRICONEX8110、TRICONEX8111、TRICONEX8112

Main processor module:TRICONEX3006、TRICONEX3007、TRICONEX3008、TRICONEX3009

Power Module:TRICONEX8310、TRICONEX8311、TRICONEX8312

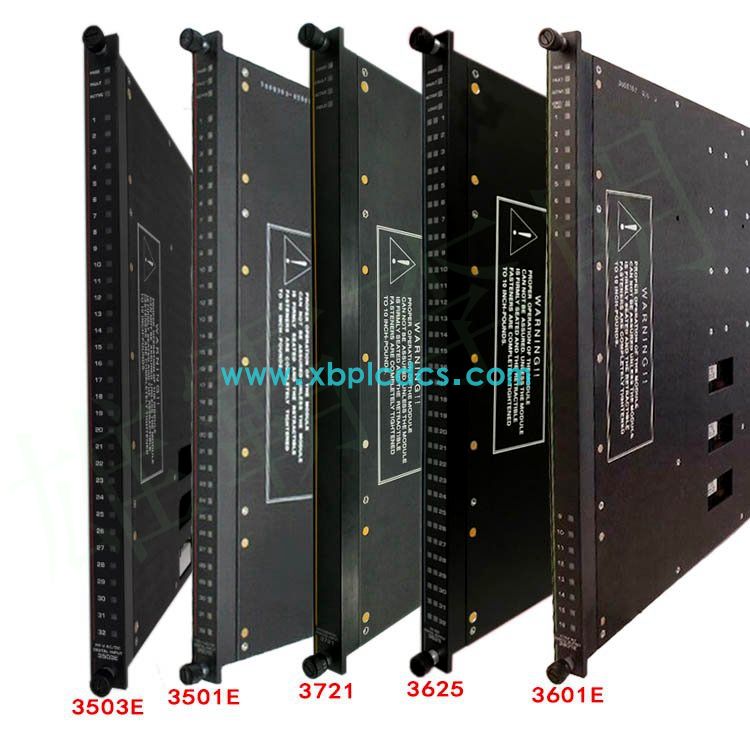

TMR Digital input module:TRICONEX3501E、TRICONEX3502E,TRICONEX3503E、TRICONEX3504E,TRICONEX3505E、TRICONEX3564、TRICONEX3506X

TMR Pulse Input Module:TRICONEX3510、TRICONEX3511

TMR Analog Input Module:TRICONEX3700、TRICONEX3700A、TRICONEX3701,TRICONEX3708E、TRICONEX3721、TRICONEX3720,TRICONEX3703E、TRICONEX3704E、TRICONEX3706E

Communication Module:TRICONEX4351B、TRICONEX4119,TRICONEX4509、TRICONEX4609、TRICONEX4429,TRICONEX4329、TRICONEX4352A、TRICONEX4409

TMR Digital Output Module:TRICONEX3624、TRICONEXV3625、TRICONEX3627,TRICONEX3627、TRICONEX3614E、TRICONEX3623,TRICONEX3664、TRICONEX3667、TRICONEX3636R,TRICONEX3607E、V3608E、TRICONEX3611E,TRICONEX3615E、TRICONEX3613E、TRICONEX3617E,TRICONEX3601E/T、TRICONEX3603E、TRICONEX3604E

Woodward is an independent designer, manufacturer and service provider of energy control and optimization solutions for aerospace and industrial markets. For 150 years, Woodward has focused its resources and expertise on delivering proven systems that perform under incredible demands. Our customers have come to rely on us to help them address and solve the challenges associated with global efficiency initiatives – from reducing emissions, to increasing energy efficiency, to helping them introduce alternative energy sources.

Model display

9907-164、9907-162、9907-149、9905-973

9907-165,9907-167,8440-2145,8406-113 ,8516-038

8446-1019,8237-1600,8200-1300,5501-471

5501-470,5501-467,5466-409,5466-316,5466-258