News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Brand:BENTLY

- Product ID:3500/22M key phase module

- Place of Origin:USA

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

3500/22M usually refers to the 3500/22m key phase module in the Bently 3500 monitoring system, which is described in detail below:

Basic function

The key phase module is mainly used to provide the phase reference signal of the machine shaft. By monitoring the key phase mark installed on the rotating shaft (usually a single tooth or groove), it accurately determines the rotation position and speed of the shaft, providing an accurate phase reference for other monitoring modules, so as to perform more accurate analysis and diagnosis of the vibration, displacement and other parameters of the machine.

Working principle

When the key phase mark on the axis passes through the key phase sensor, the sensor generates a pulse signal. The 3500/22M module receives this pulse signal and processes and analyzes it. By measuring the time interval of the pulse signal, the module can calculate the rotational speed of the shaft. At the same time, the specific position of the axis in each rotation period is determined based on the pulse signal, which provides reference for the phase measurement in vibration analysis.

Performance characteristics

High-precision measurement: The speed and phase of the shaft can be accurately measured to provide accurate data for the condition monitoring of the machine.

High reliability: Redundant power input design ensures normal operation when the power supply fails or fluctuates. With self-diagnosis function, it can monitor the working status of the module itself in real time, and alarm it in time once the fault is found.

Flexible configuration: Parameters can be set and configured through software to adapt to the monitoring needs of different machines. For example, you can adjust the key phase threshold, filter parameters, and so on.

Easy integration: As part of the Bentley 3500 monitoring system, it can be seamlessly integrated with other 3500 series modules (such as vibration monitoring module, displacement monitoring module, etc.) to form a complete machine condition monitoring system.

Application scenario

Rotating machinery monitoring: widely used in various rotating machinery status monitoring, such as steam turbines, generators, compressors, pumps and so on. By monitoring the speed and phase of the shaft, combined with the monitoring of other parameters such as vibration and temperature, the potential faults of the machine can be found in time, such as unbalance, misalignment, bearing wear, etc., providing a basis for the maintenance and repair of the equipment to avoid the shutdown and loss caused by equipment failure.

Industrial automation: In some industrial automation systems requiring precise control of shaft rotation position and speed, the 3500/22M key phase module can provide critical phase reference signals to ensure stable operation and accurate control of the system.

Bently's 1900/65A usually refers to its vibration monitoring protection instrument products, the following from the product functions, technical characteristics, application scenarios and other aspects for you to introduce in detail:

Function overview

Bentley 1900/65A Vibration monitoring protection instrument is used for continuous monitoring of rotating machinery vibration equipment, mainly for real-time measurement and evaluation of machine vibration conditions. It can receive the signal from the vibration sensor, analyze and process the vibration data, and then display the vibration value in an intuitive way, and send an alarm signal in time when the vibration exceeds the preset safety range, so as to protect the safe operation of the machine and equipment and avoid equipment damage or production accidents caused by excessive vibration

The Bentley 3500/15 is the power module in the Bentley 3500 monitoring system, which provides a stable and reliable power supply to other modules throughout the system. The following is the detailed information about it:

Functional use

Power supply: Provide stable power supply for various monitoring modules within the 3500 frame, such as displacement monitoring module, vibration monitoring module, etc., to ensure that these modules can work normally, and accurately collect and process the operation data of industrial equipment.

Redundancy: The system can be configured as a redundant power supply system. When one power supply module fails, the other power supply module continues to supply power for the system, ensuring the uninterrupted running of the monitoring system and improving the reliability and stability of the system to prevent monitoring data loss or device loss due to power failure.

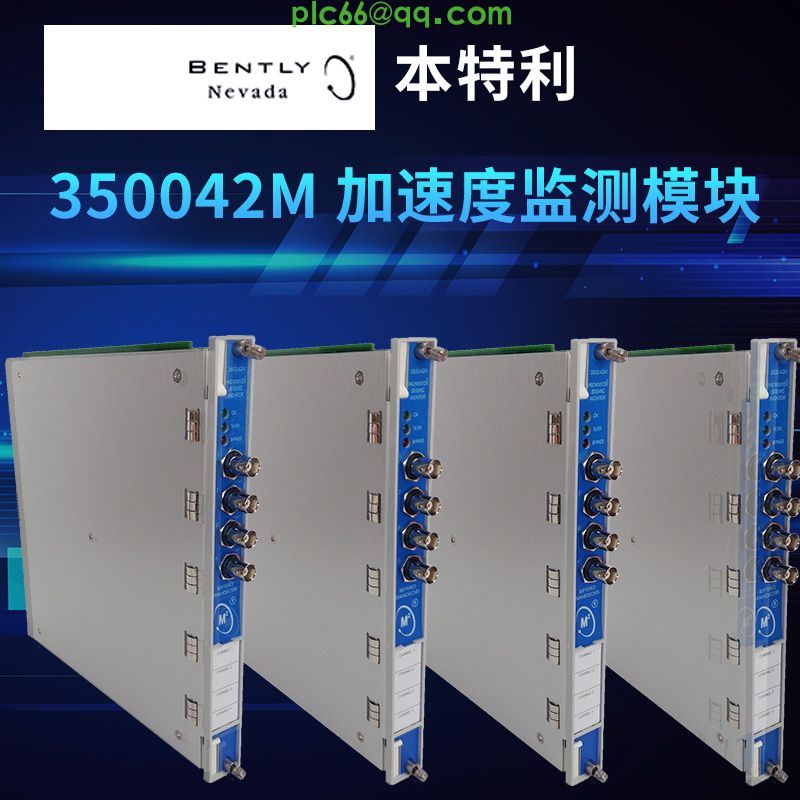

Bentley 3500/42 is a key module in the Bentley 3500 monitoring system, full name 3500/42M vibration/displacement monitor, mainly used for accurate monitoring and analysis of vibration and displacement of rotating machinery. The following is a detailed introduction to its relevant information:

Functional characteristics

Multi-parameter monitoring

Multiple mechanical parameters can be measured simultaneously, such as amplitude and phase of vibration, as well as shaft displacement. It can monitor the radial vibration, axial displacement, eccentricity and differential expansion of the shaft in real time, and fully reflect the running state of the rotating machinery.

High precision measurement

Advanced signal processing technology and high-precision sensor interface are adopted to ensure the accuracy and reliability of measurement data. Its measurement accuracy can meet the strict requirements of mechanical condition monitoring in industrial field, and can detect small vibration changes and displacement deviations, providing strong support for early fault diagnosis.

Flexible configuration

Users can flexibly configure the monitor through software according to the actual application requirements. For example, different measurement ranges, alarm thresholds, filtering parameters, etc. can be set to adapt to different types and specifications of rotating machinery.

Real-time alarm function

When the monitored parameter exceeds the preset alarm threshold, the 3500/42 module will immediately send an alarm signal. The alarm mode includes the local indicator light flashing, relay output, etc., which can timely remind the operator to take corresponding measures to avoid further deterioration of the equipment failure.

Data storage and transmission

With certain data storage capabilities, you can record historical measurement data and alarm events. At the same time, it supports communication with other modules in the Bentley 3500 system and the upper computer, and transmits monitoring data to the monitoring center through standard communication interfaces (such as Ethernet, RS-485, etc.), which is convenient for remote monitoring and data analysis.

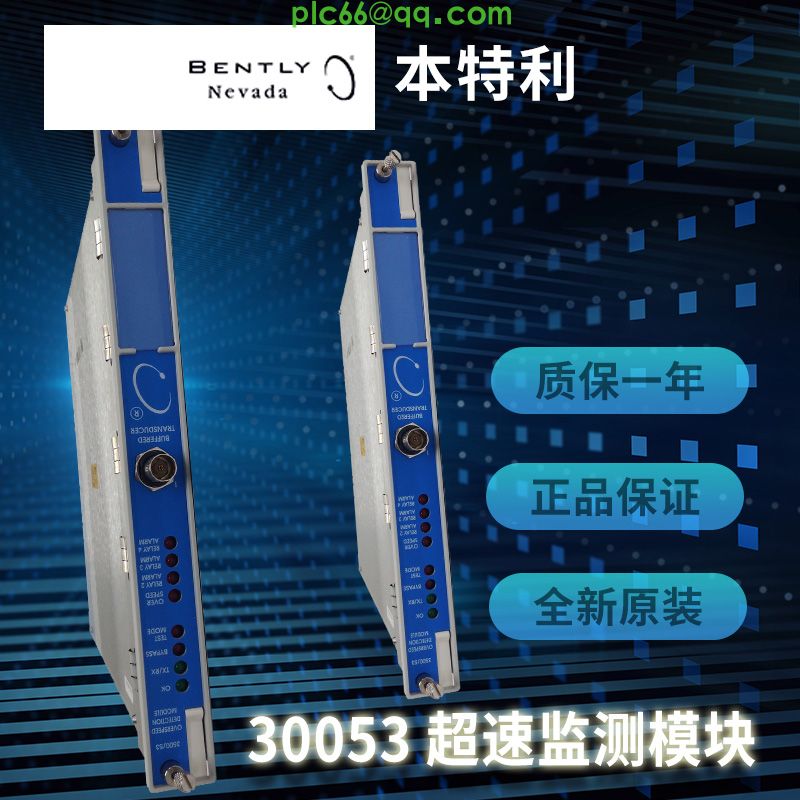

Bentley 3500/53 is the speed measurement module in the Bentley 3500 monitoring system, which plays an important role in the status monitoring of rotating machinery. The following is the relevant information for you:

Functional use

Speed measurement: The core function of this module is to accurately measure the speed of rotating machinery. It can receive signals from speed sensors (such as magnetoelectric sensors, eddy current sensors, etc.), and process and analyze the signals to calculate the speed of the shaft. Whether the equipment is running at low speed or high speed, the 3500/53 can provide accurate speed data.

Overspeed protection: overspeed alarm and tripping threshold can be set. When the detected speed exceeds the set safety range, the module will immediately trigger the alarm signal to remind the operator to take measures; If the speed continues to rise and reaches the tripping threshold, the module will output a control signal to make the equipment stop in an emergency, so as to prevent the equipment from being damaged due to overspeed operation and ensure the safety of personnel and equipment.

Phase measurement: In addition to speed measurement, it can also measure the phase information of the shaft. The phase data is of great significance for analyzing the vibration characteristics of rotating machinery and judging whether the equipment has unbalance and misalignment faults. By combining the speed and phase information, a more comprehensive understanding of the operating status of the equipment can be obtained.

The Bentley 3500/60 is the relay module in the Bentley 3500 monitoring system, which plays a key role in the condition monitoring and protection of industrial rotating machinery. The following aspects are detailed for you:

Functional use

Alarm output: As a relay module, one of its main functions is to output an alarm signal through the action of the relay contact when the 3500 monitoring system detects the abnormal operating status of the equipment. For example, when vibration, displacement, speed and other monitoring parameters exceed the preset alarm threshold, the 3500/60 module will trigger the corresponding relay action, and these signals can be connected to the sound and light alarm, remote monitoring system or other control equipment to remind the operator to take measures in time.

Equipment protection control: In addition to the alarm function, the module can also realize the protection control of the equipment. When a serious equipment failure or dangerous situation is detected, the 3500/60 module can output a control signal through the relay to make the equipment emergency shutdown or take other protective measures to prevent further damage to the equipment and ensure the safety of personnel and equipment.

Technical characteristics

Multiple relay channels: There are usually multiple independent relay channels, each of which can be configured and controlled independently. This enables it to handle multiple different types of alarm and control signals simultaneously to meet the needs of complex industrial applications. For example, separate relay outputs can be set up for vibration alarm, temperature alarm, overspeed alarm, etc.

High reliability design: Redundant power input and fail-safe design concept are adopted to ensure that when the power supply fails or the module itself fails, it can maintain a safe state. Relay contacts have a high load capacity and life, can reliably switch high voltage, high current circuit, adapt to the harsh working environment of industrial sites.

Flexible configuration options: Users can flexibly configure the action logic, delay time, reset mode and other parameters of the relay through the software. For example, the relay can be set to act immediately after the alarm signal appears, and a certain delay time can be set to avoid misoperation; You can also select the automatic reset or manual reset mode to adjust as required.

Status indicator function: The module is equipped with a clear status indicator, which is used to display the working status of each relay (such as suction, release) and the power status of the module. This allows the operator to intuitively understand the working condition of the module and facilitate routine maintenance and troubleshooting.

Bentley 3500/92 is a communication gateway module in the Bentley 3500 monitoring system, which plays an important role in the data transmission and interaction of the entire monitoring system. The following describes its functional characteristics and application scenarios in detail:

Functional characteristics

Multi-protocol communication support

The Bentley 3500/92 module supports a variety of communication protocols, such as Modbus TCP, Ethernet/IP, etc. This enables it to communicate seamlessly with different types of control systems, upper computer software, and other industrial equipment, facilitating data sharing and integration. For example, it can transmit the vibration, displacement and other data of rotating machinery collected by the 3500 monitoring system to the PLC control system through the Modbus TCP protocol for further analysis and control.

Data transmission and sharing

The module can centrally process the data collected by each monitoring module in the 3500 system, and transmit it to the remote monitoring center or other equipment that needs data through the network. It can transmit the operating status information of the equipment in real time and accurately, including real-time measurement value, alarm status, historical data, etc., which is convenient for operators to carry out remote monitoring and fault diagnosis.

Flexible configuration mode

Users can flexibly configure the 3500/92 module through software, including setting communication parameters (such as IP address and port number), adjusting the data transmission period, and defining data mapping relationships. This flexibility allows the modules to adapt to different industrial network environments and application requirements.

Data processing and conversion

It has certain data processing capabilities, and can filter, scale, calculate and other operations on the collected data to convert the original data into more valuable information. For example, the analog signal collected by the vibration sensor is converted into specific vibration amplitude and frequency data, and the necessary unit conversion is carried out.

Redundant communication function

Some 3500/92 modules support redundant communication configurations, that is, two independent communication links can be used simultaneously for data transmission. When one link fails, the system automatically switches to another link to ensure the continuity and reliability of data transmission and improve the stability of the entire monitoring system.

The 3500/22M is a transient data interface module in the Bently Nevada 3500 series, and here are some related models of the 3500/22M:

3500/05: Instrument bracket, which is the base component of the 3500 system and is used to mount other modules.

3500/15: Power module that provides power support to other modules in the 3500 system, one or two 3500/15 power supplies can be used in a 3500 rack.

3500/20: The rack interface module (RIM), which can realize the connection and communication between the rack and other devices or systems, the 3500/22M combines some of the functions of the 3500/20 with the data collection capabilities of the communication processor.

3500/25: The key phase module provides phase reference information to the 3500 frame, receives input signals from proximity probes or magnetic pickups, and converts them into digital timing measurements for measuring machine speed and vector parameters.

3500/32:4 channel relay module can control the relay action of 4 channels according to the setting value and logic of the monitoring system to achieve the protection and control of the equipment.

3500/33:16 channel relay module, with 16 channel relay control function, can control more relay output than 3500/32.

3500/40M: The proximity monitor is used to monitor the parameters of the adjacent position of the device. It can cooperate with 3500/22M to transmit and process the monitoring data through 3500/22M.

3500/42M: Prox/seismic monitor, which can monitor the vibration of the equipment, etc., and provide the data to 3500/22M for further processing and transmission.

3500/92: Communication gateway module to realize the communication connection between the 3500 system and other external systems or networks, and to complete the data interaction and remote monitoring functions of the system together with 3500/22M.

3500/94: VGA display, used to display the relevant data and information of the 3500 system, and work with the 3500/22M, so that the operator can visually view the monitoring data and system status.