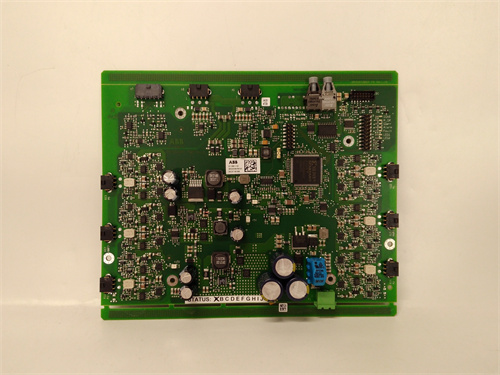

In the ever-evolving realm of industrial automation and advanced engineering, the LT2005-S/SP19 3BHB014827R0001 stands as a remarkable testament to cutting-edge technology and meticulous design. This high-performance industrial component, likely developed by a leading entity such as ABB, has carved a niche for itself in various industrial applications, offering unparalleled functionality, reliability, and efficiency.

The LT2005-S/SP19 3BHB014827R0001 is not just another industrial part; it is a sophisticated device engineered to meet the stringent demands of modern industrial environments. Whether it's in large-scale manufacturing plants, power generation facilities, or complex process industries, this component plays a pivotal role in ensuring seamless operation and optimal performance of the systems it is integrated into.

- Electrical Prowess

- Power Input Adaptability: The LT2005-S/SP19 3BHB014827R0001 is designed to accommodate a diverse range of power sources. With its ability to handle both AC and DC power inputs, it can operate within a wide voltage spectrum, typically spanning from [lower voltage limit] to [higher voltage limit]. This flexibility ensures that the component can be seamlessly integrated into various electrical systems, regardless of regional or industrial-specific power requirements.

- Signal Processing Precision: At its core, this component excels in signal processing. It can efficiently manage a plethora of electrical signals, including analog signals with a remarkable precision. For instance, it can accurately handle analog inputs in the range of 0 - 10V or 4 - 20mA, with an impressive accuracy of up to ±[accuracy percentage] of the full scale. Digital signals are also processed with equal finesse, enabling seamless communication and control within the industrial ecosystem.

- Robust Communication Interfaces: Equipped with a comprehensive suite of communication interfaces, the LT2005-S/SP19 3BHB014827R0001 ensures smooth data exchange and connectivity. The Ethernet interface, in particular, supports popular communication protocols such as Modbus TCP and Profinet, facilitating high-speed data transfer and enabling remote monitoring and control. Additionally, the presence of RS-485 and RS-232 serial communication interfaces provides further flexibility, allowing for seamless integration with legacy systems and other devices.

- Mechanical Resilience

- Compact and Versatile Design: The component features a compact form factor, making it easy to install in a variety of industrial settings. Its dimensions, carefully optimized for space efficiency, allow for hassle-free integration into control cabinets, machinery, or other equipment. The installation process is further simplified by its multiple mounting options, including rail mounting and panel mounting, catering to the specific needs of different applications.

- Superior Protection Against the Elements: With a commendable protection rating, such as IP[protection rating number], the LT2005-S/SP19 3BHB014827R0001 is well-equipped to withstand harsh industrial environments. It effectively shields against dust, moisture, and other contaminants, ensuring its reliable operation even in the most challenging conditions. This robust protection not only enhances the component's lifespan but also minimizes the need for frequent maintenance and replacement.

- Adaptive Operational Environment

- Wide Temperature Tolerance: The component is engineered to function optimally within a broad temperature range, typically from [lower temperature] to [higher temperature]. This adaptability makes it suitable for use in various geographical locations and industrial processes, where temperature fluctuations can be significant. Whether it's the scorching heat of a steel mill or the frigid cold of a refrigeration facility, the LT2005-S/SP19 3BHB014827R0001 can maintain its performance without compromising on functionality.

- Humidity Resistance: In addition to its temperature resilience, the component also exhibits excellent resistance to humidity. It can operate flawlessly in environments with relative humidity levels ranging from [lower humidity] to [higher humidity] (non-condensing), ensuring its reliability in areas prone to moisture, such as coastal regions or food processing plants.

- Precision Control and Optimization

- Advanced Control Algorithms: The LT2005-S/SP19 3BHB014827R0001 incorporates state-of-the-art control algorithms, such as PID control, which enable precise regulation of industrial processes. Whether it's controlling the speed of a motor, the flow of a fluid, or the temperature of a reaction vessel, this component can achieve the desired setpoints with remarkable accuracy. The ability to fine-tune these algorithms allows for optimal performance and energy efficiency, reducing operational costs and enhancing productivity.

- Real-time Monitoring and Adjustment: With its built-in sensors and monitoring capabilities, the component can continuously monitor the status of the system it is controlling. In the event of any deviations from the desired parameters, it can quickly detect and initiate corrective actions in real-time. This proactive approach to control ensures that the industrial process remains stable and efficient, minimizing the risk of downtime and product quality issues.

- Reliability and Fault Tolerance

- Comprehensive Fault Diagnosis: The LT2005-S/SP19 3BHB014827R0001 is equipped with an advanced fault diagnosis system that can identify and isolate potential issues within the system. It can detect a wide range of faults, including overcurrent, overvoltage, overheating, and communication errors, among others. Once a fault is detected, it can generate detailed diagnostic reports, enabling technicians to quickly pinpoint the root cause and take appropriate corrective measures.

- Redundancy and Backup Mechanisms: To further enhance its reliability, the component features redundancy and backup mechanisms. In the event of a component failure or a critical system error, these mechanisms can automatically take over, ensuring uninterrupted operation of the industrial process. This built-in resilience minimizes the impact of failures on production, reducing downtime and associated costs.

- Flexibility and Customization

- Programming and Configuration Freedom: The component supports multiple programming languages, including ladder logic, function block diagram, and structured text, providing engineers with the flexibility to develop customized control programs tailored to the specific requirements of their applications. The intuitive programming environment allows for easy configuration and modification of the component's parameters, enabling quick adaptation to changing process needs.

- Scalability and Integration: The LT2005-S/SP19 3BHB014827R0001 is designed to be scalable, allowing for easy expansion and integration with other industrial components and systems. Whether it's adding new sensors, actuators, or control modules, this component can seamlessly integrate into existing setups, enabling the growth and evolution of the industrial automation infrastructure.

- Industrial Automation

- Manufacturing Excellence: In the manufacturing industry, the LT2005-S/SP19 3BHB014827R0001 plays a crucial role in automating production processes. From automotive assembly lines to electronics manufacturing facilities, it enables precise control of robots, conveyors, and other machinery, ensuring high-quality production and increased efficiency. By optimizing the production process, this component helps manufacturers reduce waste, improve productivity, and stay competitive in the global market.

- Process Optimization: In process industries such as chemical, oil and gas, and pharmaceuticals, the component is used to control and monitor complex processes. It can regulate the flow of chemicals, control the temperature and pressure of reactors, and ensure the quality of the final products. The ability to achieve precise control and real-time monitoring helps improve process efficiency, reduce energy consumption, and enhance product quality, ultimately leading to increased profitability.

- Power Generation and Distribution

- Power Plant Operation: In power plants, the LT2005-S/SP19 3BHB014827R0001 is used to control and monitor various aspects of power generation, including the operation of generators, turbines, and transformers. It ensures the stable and efficient production of electricity, minimizing downtime and maximizing the output of the power plant. By optimizing the power generation process, this component helps reduce emissions and improve the overall sustainability of the power industry.

- Grid Management: The component also plays a vital role in power grid management. It can monitor the flow of electricity in the grid, detect and respond to fluctuations in demand, and ensure the stability and reliability of the power supply. By enabling real-time monitoring and control of the power grid, this component helps prevent power outages, reduce transmission losses, and improve the efficiency of the power distribution system.

- Mechanical Engineering

- Machine Tool Control: In the field of mechanical engineering, the LT2005-S/SP19 3BHB014827R0001 is used to control the operation of machine tools, such as lathes, mills, and drills. It enables precise control of the cutting process, ensuring the accuracy and quality of the machined parts. By optimizing the performance of machine tools, this component helps manufacturers improve productivity, reduce production costs, and enhance the competitiveness of their products.

- Robotics and Automation: The component is also essential in the development of robotics and automation systems. It can control the movement and operation of robots, enabling them to perform complex tasks with precision and accuracy. By integrating the LT2005-S/SP19 3BHB014827R0001 into robotics and automation systems, manufacturers can improve the efficiency and productivity of their operations, reduce labor costs, and enhance the quality of their products.