News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

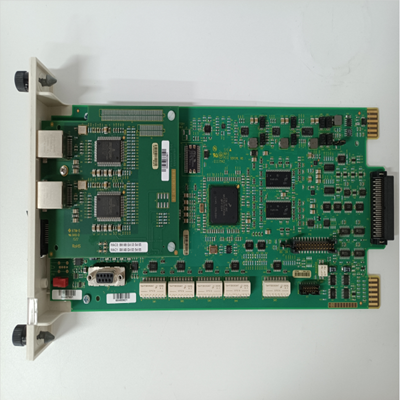

GFD563A102 3BHE046836R0102 is a programmable logic controller (PLC) of the AC800PEC family produced by ABB. Here's how:

Feature

GFD563A102 3BHE046836R0102 Programmable Logic Controller (PLC) Powerful processing power: PowerPC 405 processor, clock speed of 200MHz, with 256MB RAM and 512MB flash memory, can quickly process various instructions and data, can achieve fast and accurate control response, to meet the high precision and high dynamic response control requirements.

GFD563A102 3BHE046836R0102 Programmable Logic Controller (PLC) Rich I/O interfaces: Provides 64 digital input, 64 digital output, 16 analog input and 16 analog output, can connect a variety of sensors, actuators and other equipment, to achieve complex control logic and automation process, support motion control, logic control, data acquisition and other functions.

GFD563A102 3BHE046836R0102 Programmable Logic Controller (PLC) Multiple communication protocols: Support Ethernet, RS-232, RS-485, Profibus DP, Modbus TCP/IP and other communication protocols, easy to communicate and integrate with other devices and systems, can achieve remote monitoring and control.

Flexible configuration options: Users can customize IO interface configuration, control algorithm selection, and motion trajectory planning based on application requirements to meet different control scenarios and requirements.

Perfect protection function: Using high-quality electronic components and advanced production technology, with overcurrent, overvoltage, overheating and other protection functions to ensure stable operation and long life of the equipment.

Usage method

Installation: Install the device according to the installation guide provided by ABB. Install the device in an appropriate control cabinet, ensure that the installation position meets the requirements for heat dissipation and dust resistance, and correctly connect the power supply and input and output signal cables.

Programming: Using the corresponding programming software, according to the specific control tasks, by writing logic programs to achieve the required control functions, such as the realization of the start and stop control of the equipment on the production line, the monitoring and adjustment of temperature, pressure and other parameters.

Configuration: Through programming software or related configuration tools, configure various parameters of the PLC, such as setting communication parameters to communicate with other devices, and configuring the working mode of the I/O module.

Debugging and maintenance: After the installation and programming is completed, system debugging is carried out to check whether the operation of the program meets the expectations, monitoring the operating status of the equipment, and discovering and solving possible problems in time. During the running process, perform regular maintenance, including checking whether the hardware connection is loose and whether the software needs to be updated