Bently Nevada’s Electronic Overspeed Detection System

for the 3500 Series Machinery Detection System provides

a highly reliable, fast response, redundant tachometer

system intended specifically for use as part of an

overspeed protection system. It is designed to meet the

requirements of American Petroleum Institute Standards

670 and 612 pertaining to overspeed protection.

3500/53 modules can be combined to form a 2-out-of-2 or

2-out-of-3 (recommended) voting system.

The use of redundant power supplies in a 3500 rack

containing the Overspeed Detection System is required.

3500/53 Electronic Overspeed Detection Syste

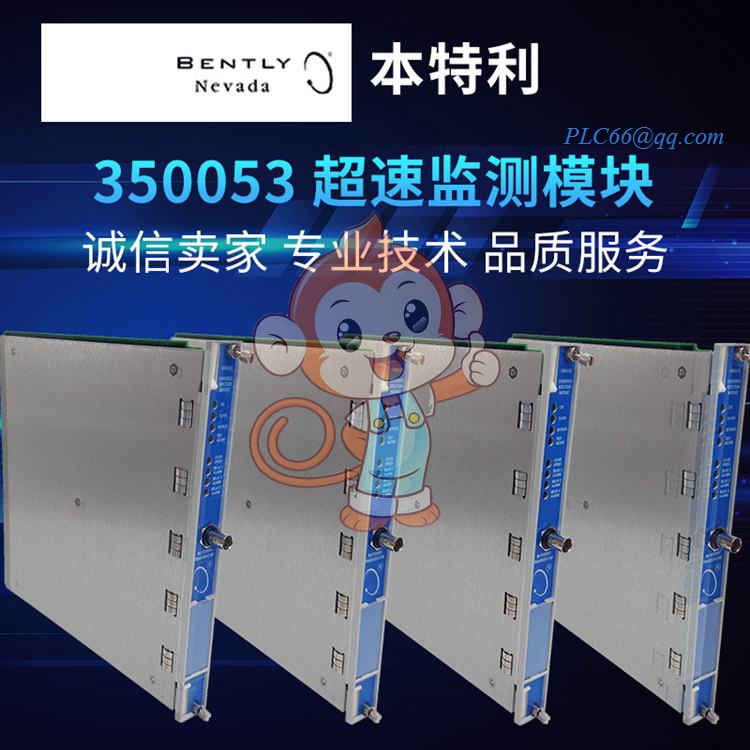

The Bently Nevada 3500/53 Electronic Overspeed Detection System stands as a crucial and highly reliable component within the industrial machinery protection landscape. As an integral part of the renowned 3500 series machinery monitoring system, it adheres to the stringent standards of API 670 and 612, ensuring top-notch performance in safeguarding against the peril of overspeed.

One of the most remarkable aspects of the 3500/53 is its exceptional reliability. Thanks to its redundant design, encompassing redundant power supplies and tachometers, it can maintain seamless operation even in the face of a single component failure. This robust architecture instills confidence in industrial operators, knowing that their valuable machinery is well-protected.

Speed is of the essence when it comes to overspeed protection, and the 3500/53 excels in this regard. It boasts real-time monitoring capabilities, constantly keeping a vigilant eye on the rotational speed of mechanical equipment. The moment the speed breaches the predefined limit, it swiftly and accurately sends out alarm signals, providing operators with precious time to take corrective action and prevent potentially catastrophic accidents.

The system's versatility is further enhanced by its wide compatibility with various types of sensors. Whether it's eddy current sensors or magnetic sensors, the 3500/53 can readily accept signals, making it adaptable to different machinery setups. This flexibility simplifies the integration process and allows for seamless operation across a diverse range of industrial applications.

Configuration and maintenance are made a breeze with the 3500/53. Equipped with user-friendly configuration software and an intuitive interface, it empowers technicians to easily configure, debug, and maintain the system. This not only saves time but also reduces the risk of errors, ensuring optimal performance at all times.

In terms of output options, the 3500/53 offers a wealth of choices. From proportional output values to recorder output and relay output, users have the freedom to select the most suitable option based on their specific requirements. Additionally, it supports voting systems, such as the 2-out-of-2 or 2-out-of-3 configurations, adding an extra layer of reliability and safety.

With its technical specifications, the 3500/53 showcases its precision and efficiency. It can handle input signals from a range of +10.0 V to -24.0 V with an input impedance of 20 kΩ. The system has a relatively low power consumption of typically 8.0 W, making it energy-efficient. The single-pole, double-throw (SPDT) relays, complete with epoxy sealing and arc suppressers as standard, ensure reliable switching operations.

The frequency response speed input is highly versatile, supporting 1 to 255 events per revolution, with a maximum full-scale range of 99,999 rpm and a maximum input frequency of 20 kHz. The system also offers excellent resolution and update rate, with a resolution of 0.3662 µA per bit and an update rate of approximately 100 ms, ensuring accurate and timely speed monitoring.

The Bently Nevada 3500/53 Electronic Overspeed Detection System finds widespread applications across various industries. From power generation plants, where the safety of turbines is of utmost importance, to oil and gas refineries, chemical plants, and manufacturing facilities, this system plays a vital role in protecting valuable machinery and ensuring uninterrupted production.

In conclusion, the 3500/53 Electronic Overspeed Detection System is a state-of-the-art solution that combines reliability, speed, versatility, and ease of use. Its advanced features and robust design make it a preferred choice for industrial operators seeking to safeguard their machinery and enhance operational efficiency. Whether it's preventing costly breakdowns or ensuring compliance with industry standards, the 3500/53 is a trusted ally in the world of industrial machinery protection.

3500/53 Electronic Overspeed Detection System is a module in Bently Nevada's 3500 series of mechanical monitoring systems, which are typically overspeed detection modules. Here are some of its features and related information:

- Functional aspects:

It is mainly used to monitor the speed of rotating equipment, and can accurately detect whether the equipment is speeding. For some equipment with strict speed requirements and high-speed rotation, such as steam turbines, compressors, fans, etc., the overspeed detection function of the module is very important, which can detect the abnormal speed of the equipment in time to avoid equipment damage, failure and even safety accidents caused by overspeed.

With high-precision measurement capabilities, the speed of the equipment can be accurately measured and compared with the preset speed threshold, and once the threshold is exceeded, the alarm signal is immediately sent.

- Connectivity and Communication:

- It can communicate and interact with other modules of the 3500 system to transmit the detected speed data to the system for real-time monitoring and analysis by the operator. Specific communication protocols and interfaces are usually used to ensure the accuracy and reliability of data transmission.

- Reliability and stability:

It has high reliability and stability in design, and can adapt to complex environmental conditions in industrial sites, such as high temperature, high humidity, strong electromagnetic interference. It has good anti-interference ability to ensure that the speed can be accurately detected in harsh environments.

Redundancy design and other technical means are adopted to improve the reliability of the system and ensure that there will be no monitoring interruption caused by module failure in the monitoring of key equipment.

Email: plc66@qq.com

Phone: +86 18059884790(WHATSAPP/WeChat)

Sales:LIMING

The price is subject to confirmation by the contact person LI MING (manager).

Product: Brand new original packaging

Payment method: 100% telegraphic transfer. Conditions can be negotiated before shipment of inventory goods!

If you have any downtime spare parts that cannot be found, please feel free to call or contact me via email at any time.

If there are any issues that the product cannot solve, please contact me.

Many products have not been listed yet. Please contact us for more products!!!

If there is any inconsistency between the product model and the displayed picture, the model shall prevail.

Please contact us for specific product pictures, and we will arrange for photos to be taken in the warehouse for confirmation

We have 22 shared warehouses worldwide, so please understand that sometimes it may take several hours to respond accurately to you.

Of course, we will respond to your concerns as soon as possible

Our company can directly purchase from overseas, can provide different countries, manufacturers of equipment and spare parts, to

solve your many places to find trouble or worry about product quality problems, etc., in the price we have a great advantage, product

details, we sincerely welcome you to inquire or use E-mail query!

The company to stop production control system parts, as the advantage of products

As long as you want, I can help you find! The price is excellent!

Main products, superior supply, adequate inventory

ABB PLC System modules DCS system modules include some discontinued control system modules. (For example :PM645B, 5SHY3545L0014,

PM630, 07AC91D, SPHSS13PP845PFEA111-20PFEA112-65 PPD113B01-10-150000, PPD115A102PPD113-B03-23-111615)

◆GE Gas Turbine clamp :IS200 series, DS200 series, etc. (e.g. IS200TRPGH1B, DS200PCCAG1A)◆Triconex: Redundant fault-tolerant control

system, the most modern fault-tolerant controller based on triple module redundancy (TMR) structure. (e.g. 3721, 3625, 3008, 4351B, 3805E)

Foxboro (Foxboro) : 1 / ASeries system, FBM (field input/output module) sequence control, etc. (for example: FBM201CP270CP4BFCP280FCP270)

Bently Nevada(Bentley):3500 system cards. (e.g. 35/15350/2M5) HIMA(Dark Horse):F8650X, F8627X, F8651X, F8652X, F35, etc

Motorola(MOTOROLA):MVME162, MVME167, MVME1772, MVME177 and other series XOOl:1/0, Vne board and processor.

(For example :XVME-653, XVME-674, XVME-976)

Rockvell (Allen-Bradley):1756, 1757, 1753, 1394 series. (Example :1756-L73XT1756-L611757-SRM)

◆Reliance: Discontinued spare parts (e.g. 0-60002-6, 5-D4022, S-D4006-D)

Westinghouse Emerson :VE3007CE3008, 5X00105G145X00119G01, 1X00416H011X00416H01

schneider :140 series processors, control cards, power modules, etc. (for example: 140 cpu67160c140cpu67260, 140 cpu65150140cpu43412140nwm110000

Medium description: ABB: Industrial robot DSQC series (series :DSQC202DSQC545A, DSQC627DSQC352DSQC679) Rexroth(Rexroth):

1/0 module PLC controller driver, etc. (e.g. TVD1.3-15-03, KDV3.1-100-220) Woodward: Control governor, etc. (e.g. 5464-414, 5466-409, 9907-164

【 Disclaimer 】

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products,

independent channels to buy such special products. Guizhou Yuanmiao Automation

Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the productsfeatured on this website. All product names/product images, trademarks, brands and logos used

on this website are the property of their respective owners. Descriptions, depictions or sales of products

bearing these names, images, trademarks, brands and logos are for identification purposes only and do

not imply any association or authorization with any rights holder