Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Brand:GE

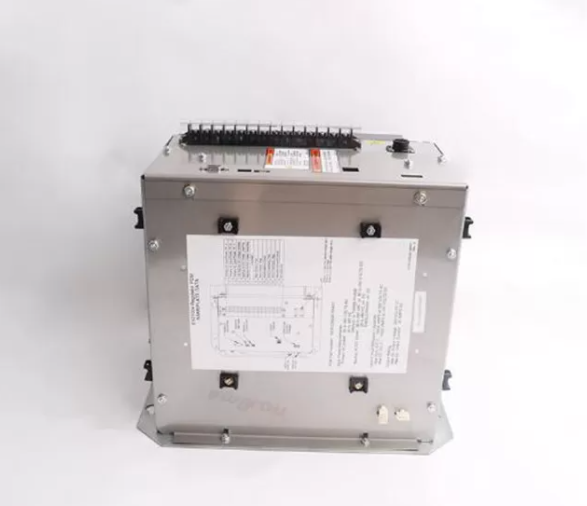

- Product ID:151X1235DB15SA01 EX2100e Regulator

- Place of Origin:USA

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

The 151X1235DB15SA01 is a gas turbine control system from GE Fanuc. It has a variety of characteristics and advantages, as follows:

Performance parameters: Rated power 12000kW, working frequency 50Hz, protection level IP54, control method PID, communication interface Modbus RTU, etc., the ambient temperature range is -40 °C to + 60°C.

Features: Advanced technology, with high accuracy and efficiency; Supports a variety of communication protocols such as Ethernet/IP and DeviceNet, which can be seamlessly integrated with existing systems to enhance connectivity and data exchange capabilities. Taking into account safety factors, in line with international standards such as UL and CE; Supports Modbus and OPC-UA interfaces for seamless communication with various automation and monitoring systems.

Design features: Modular design, easy to integrate and customize to meet various operational needs; Strong resistance to temperature and humidity to ensure stable performance in harsh environments; Energy efficient, minimizing energy consumption without compromising performance; Built with high quality materials, it is durable, reduces downtime, and offers comprehensive documentation and support services to facilitate quick installation and efficient operation.

151X1235DB15SA01 EX2100e Regulator Data acquisition and monitoring: The sensor in the control system will collect all kinds of key data in the gas turbine operation in real time, including but not limited to temperature, pressure, speed, vibration, etc. For example, the temperature sensor installed in the compressor, combustion chamber, turbine and other parts can accurately measure the temperature change of each component; The pressure sensor monitors the pressure of air and gas at different stages; The speed sensor is used to obtain the rotation speed of the rotor, which is the basis for the control system to make decisions and adjustments.

151X1235DB15SA01 EX2100e Regulator signal processing and analysis: The original data collected will be transmitted to the controller, the controller usually adopts advanced microprocessor or digital signal processor, filtering, amplification, conversion and other processing of these data, remove noise and interference, extract useful information. According to the preset algorithm and model, the processed data is analyzed to determine whether the gas turbine is in normal operating state and whether there is potential failure risk

A large power plant: In a power plant, the gas turbine control system ensures efficient and stable operation of the gas turbine under different loads by precisely regulating the fuel supply and air flow. For example, during the peak load hours of the power grid, the control system can respond quickly, increase the fuel volume, improve the output power of the gas turbine, and meet the power demand of the power grid. When the load is low, it can be adjusted in time to reduce the power output and realize energy-saving operation. At the same time, the control system also monitors the temperature, pressure, speed and other key parameters of the gas turbine in real time, and quickly takes protective measures when there is an anomaly, such as emergency shutdown, to prevent equipment damage.

Offshore oil platform: The gas turbine of an offshore oil platform not only provides power to the platform, but also drives various production equipment. Gas turbine control systems need to adapt to the harsh environmental conditions at sea, such as high temperature, high humidity, salt spray corrosion, etc. The control system will precisely control the operating state of the gas turbine according to the power demand of the platform and the production process requirements to ensure its reliability and stability under complex working conditions. For example, when the platform is carrying out oil and gas extraction operations, the control system dynamically adjusts the power output of the gas turbine according to the load changes of the mining equipment to ensure the smooth progress of production operations.

Marine power system: On a ship, the gas turbine is used as the main propulsion power unit or auxiliary power unit, and the gas turbine control system plays a crucial role. It can adjust the speed and power of the gas turbine in real time according to the ship's sailing speed, heading, load and other factors to achieve efficient propulsion of the ship. For example, when the ship accelerates, the control system rapidly increases the fuel supply of the gas turbine, increases the speed, and makes the ship obtain more power; When the ship is cruising, it is adjusted to the appropriate power state to reduce fuel consumption and improve economy.