Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Design and Construction

Functional Characteristics

Application Scenarios

In conclusion, the Triconex 5351S2 Signal processing module, with its advanced design, powerful functions, and wide range of applications, is an indispensable component in modern industrial automation and control systems, making important contributions to improving industrial production efficiency, ensuring product quality, and enhancing system safety and reliability.

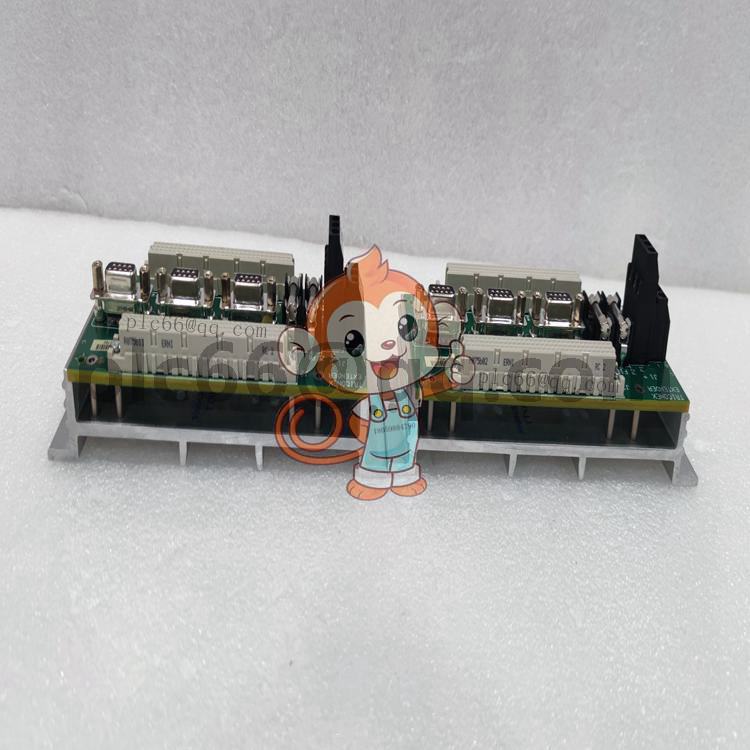

Triconex 5351S2 is a Triconex brand for industrial automation control system module, the following is the introduction of it:

Basic information

Working voltage: 24Vdc/120Vac

Output frequency: 50-60

Product certification: original factory certification

Functional characteristics

Strong signal processing ability: it can receive and process many types of signals, such as analog signals (voltage, current) and digital signals, etc., and convert the original signal from the sensor into a form that the control system can recognize and process, providing accurate data for system decision-making.

High-precision acquisition: It has high precision in signal acquisition, can ensure the accuracy of measurement results, can accurately collect temperature, pressure, flow and other parameter signals, and provide reliable support for precision process control in industrial production.

Reliable redundancy design: Support triple redundancy (TMR) configuration, there are three identical circuit channels to process signals at the same time, when one or two channels fail, the system can still rely on the normal channel stable operation, greatly improving the reliability and fault tolerance of the system.

Convenient hot swap function: With modular design and hot swap function, the module can be directly inserted and removed for maintenance or replacement during system operation without stopping, reducing maintenance time and impact on production.

Good environmental adaptability: It can adapt to harsh industrial environment, such as high temperature, high humidity, strong electromagnetic interference, etc., and can work stably for a long time under harsh conditions such as petroleum and chemical industry to ensure the continuous operation of the system.

Application field

Process control system: In the process control of chemical, petroleum, natural gas and other industries, data from various sensors can be collected and processed, such as reactor temperature, pipeline pressure, fluid flow, etc., to provide data support for process control and ensure that the production process runs stably according to predetermined parameters.

Safety instrumentation system (SIS) : used to monitor key process parameters, when the parameters are out of the safe range, it can trigger safety protection measures in time, such as emergency stopping, cutting off valves, etc., to ensure the safety of personnel and equipment.

Online monitoring and diagnosis: It can monitor key variables in industrial processes in real time to help engineers find potential problems in time, fault diagnosis and predictive maintenance, improve equipment utilization and reduce maintenance costs