News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

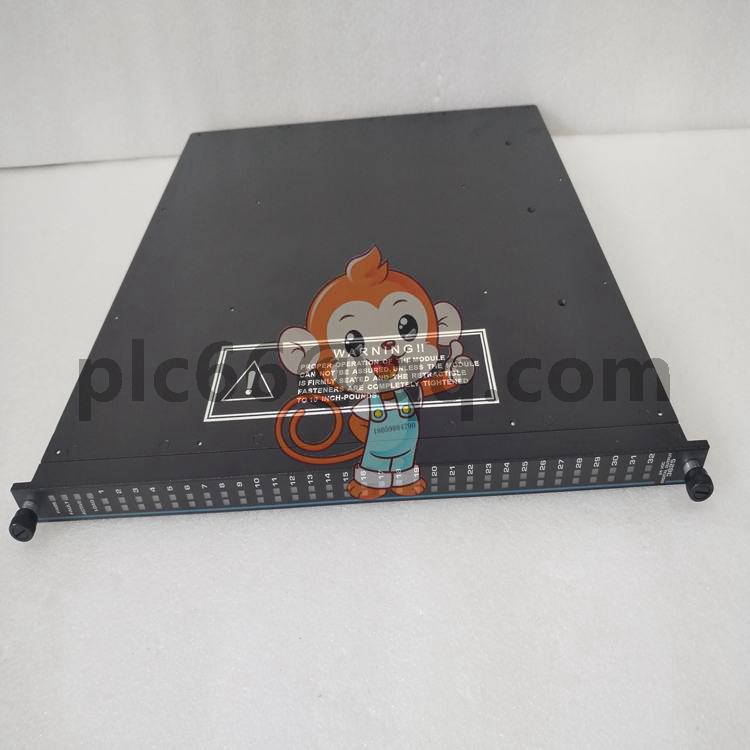

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Petrochemical industry Large ethylene plant: In the ethylene production process, HIMA 984200004 can be used to monitor key parameters such as the temperature, pressure, and feed flow rate of the cracking furnace. When abnormal parameters occur, it quickly triggers safety interlocks, such as emergency cut-off of feed and activation of the cooling system, to prevent serious accidents such as explosions caused by over-temperature and over-pressure in the cracking furnace and ensure the safe and stable operation of the ethylene plant. Crude oil tank farm: For crude oil storage tanks, this controller can monitor parameters such as tank level, oil temperature, and combustible gas concentration in real time. When the liquid level is too high or too low, the oil temperature abnormally rises, or the concentration of combustible gas leakage exceeds the standard, it promptly issues an alarm and takes corresponding safety measures, such as stopping the crude oil transfer pump and activating the fire sprinkler system, to ensure the safety of the tank farm. Power industry Wind farm: In wind turbines, HIMA 984200004 can be used to monitor the operating status of the fan, such as speed, vibration, oil temperature, and electrical parameters. When abnormal conditions such as overspeed, excessive vibration, and electrical faults are detected in the fan, it quickly triggers protection actions to safely shut down the fan, avoid equipment damage and casualties, and at the same time ensure the stable supply of electricity. Substation: In substations, it can be used to monitor the operating status of key equipment such as high-voltage switchgear and transformers, and monitor parameters such as current, voltage, and temperature in real time. When equipment malfunctions such as overload, short circuit, and overheating occur, it quickly controls the switch to trip and isolates the faulty equipment to prevent the fault from expanding and ensure the safe operation of the substation and the stability of the power system.</