News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

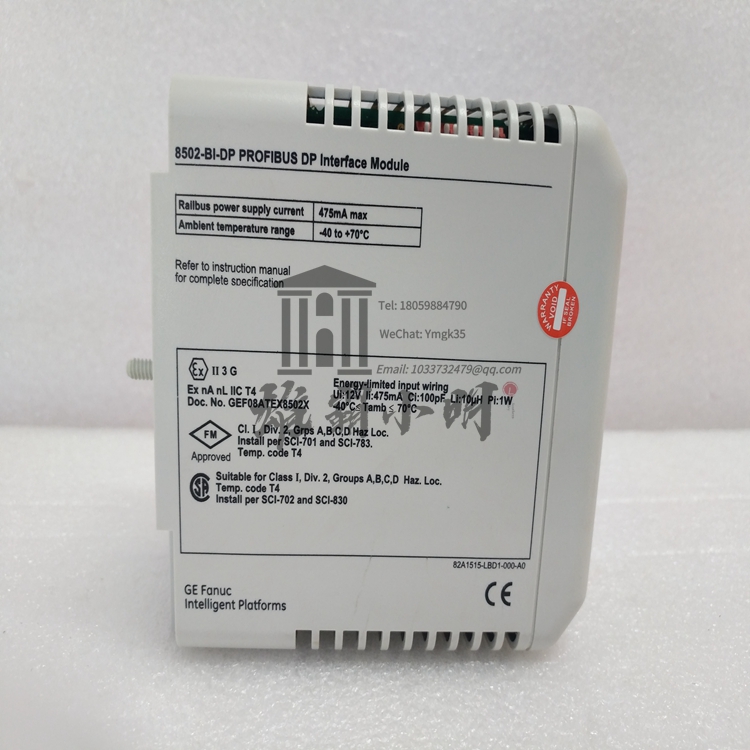

The 8502-BI-DP bus interface module (BIM) provides the communication link between the 8000Serlesio module and the Profibus-DP host. Its high-speed data acquisition from the module and LAN operation speed up to 6Mbaud allow the host to quickly respond to the control process

The BIM collects data from the 1/O module and provides it to the host as required. It is the slave of the Profibus master controller

BIM not only supports cyclic data exchange, but also supports Profibus extended diagnosis of status information. It also supports some special functions whlch has been implemented to allow high integrity system operation and in situ mismatch.

The 8502-BI-DP Bus Interface Module (BIM) provides thecommunications link between the 8000 serles l/O modules and aProfibusDp host. Its high speed acquisition of data from the modulesand LAN operation speeds of up to 6 Mbaud allows the host torespond rapidly to conditions in the control process.http://www.xbplcdcs.comThe BlM gathers the data from the l/O modules and makes itavallable to the host upon request. http://www.xbplcdcs.comit is a slave to the Profibus master.As well as cyclic data exchange, which is required for reading inputand writing output data, the BlM supports Proflbus ExtendedDlagnostics for status informatlon. it also supports a number ofspeclal features which have been implemented to allow highintegrity system operation and in-situ maintenance

PARAMETERISATION

The 8502 supports parameterisation from the Profilbus master. Thisconfigures on a "per module" basis, i.e. all the channels on a singlemodule carry the same configuration. The configuration is created ina Proflbus configurator using detalls provided in a GSD file.This method is fast and enables a configuration to be bullt basedupon “logical” modules which represent the physical modules.Modules are added one at a time to the configuration andparameters are chosen to apply to all the channels of the module.Logical modules can be selected to provide HART status and processvarlables in the Profibus-Dp cyclic input telegram. http://www.xbplcdcs.comin addition, forapplicatlons where access to many HART varlables is requlred, theHART "mailbox" can be used. This technique collects HART varlableas they are requlred: saving space in telegrams that are sometimesoverworked with data. This method is available only when usingparameterisation.

The configuration is passed down from the Proflbus master to the BlMat the start of the sesslon. if the system is stopped and re.started , theconfiguration flle is re-transmitted to the BlM.