Product

Product

News

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

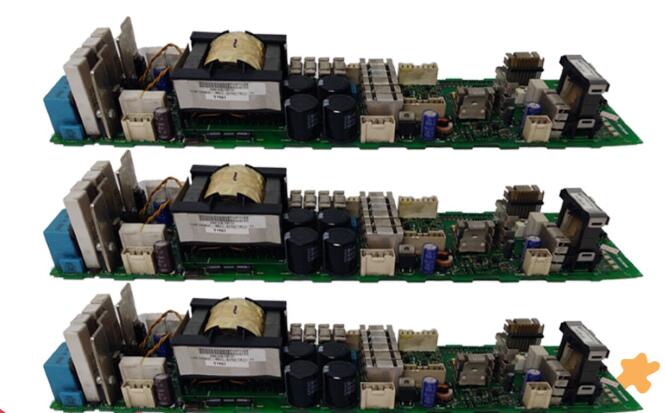

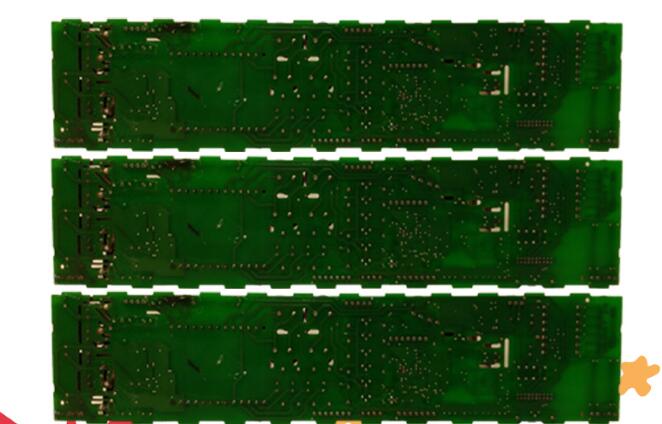

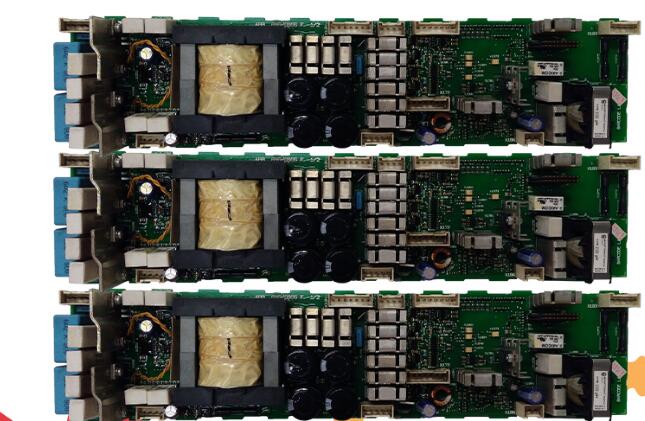

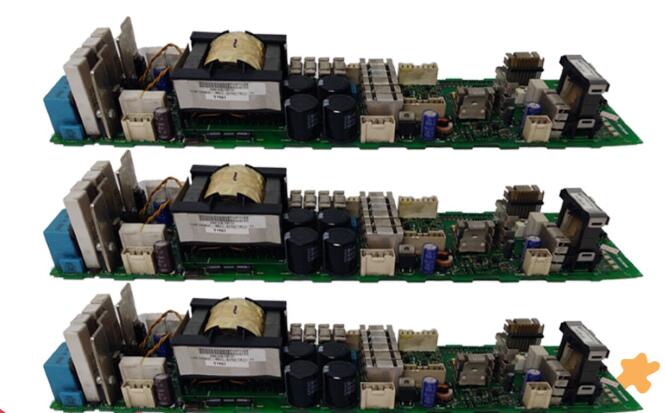

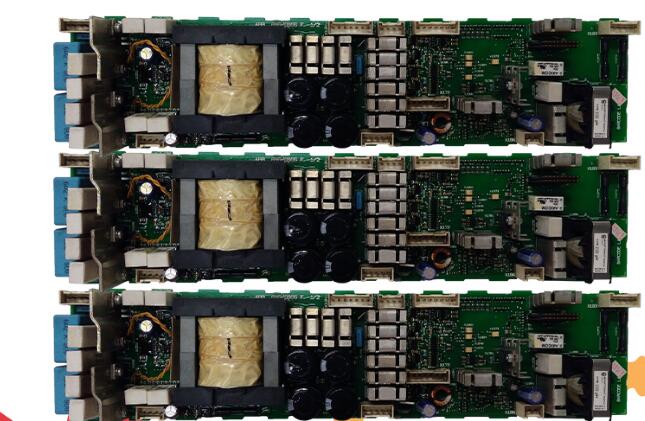

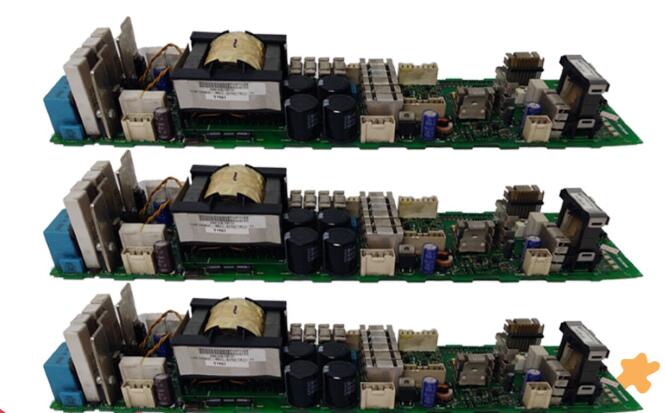

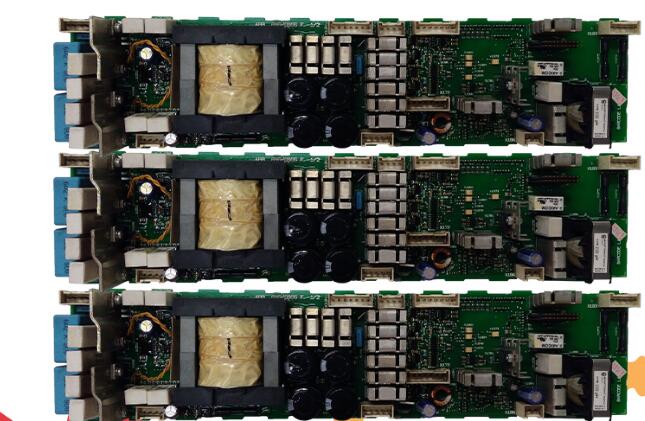

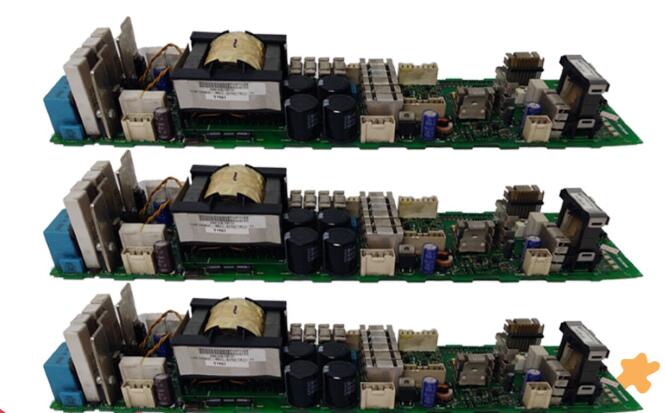

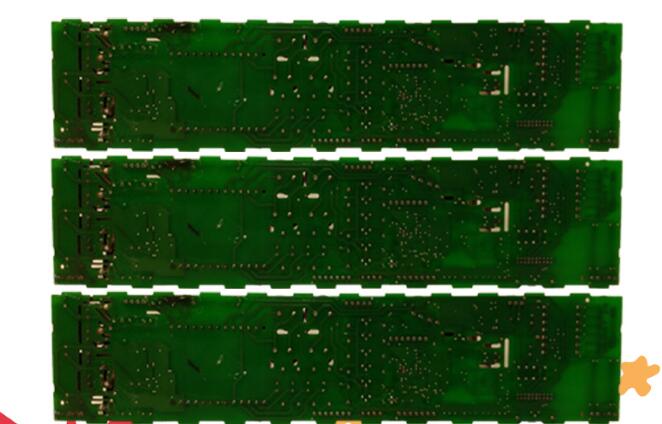

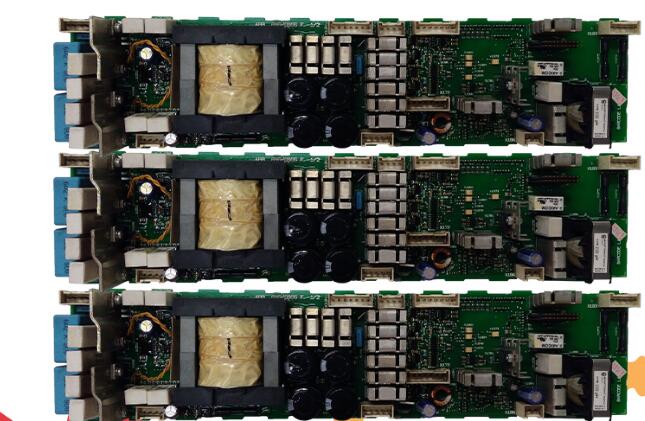

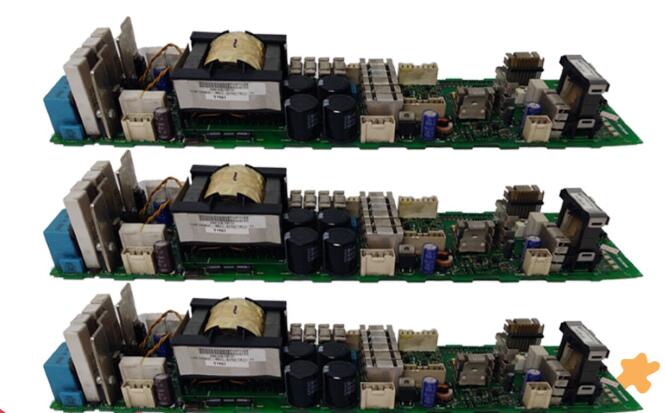

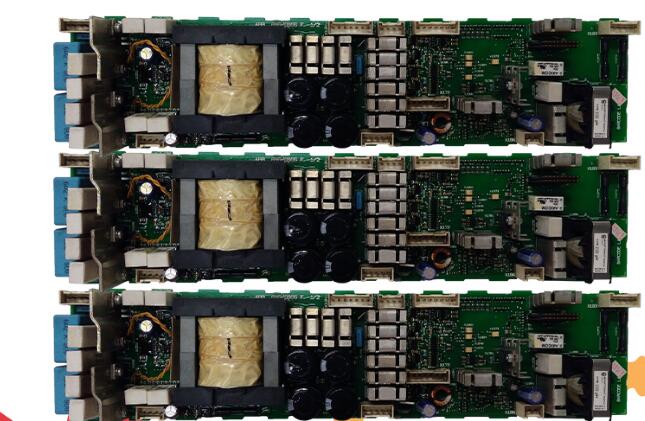

3AUA0000001306模块 kimi

- Brand:ABB

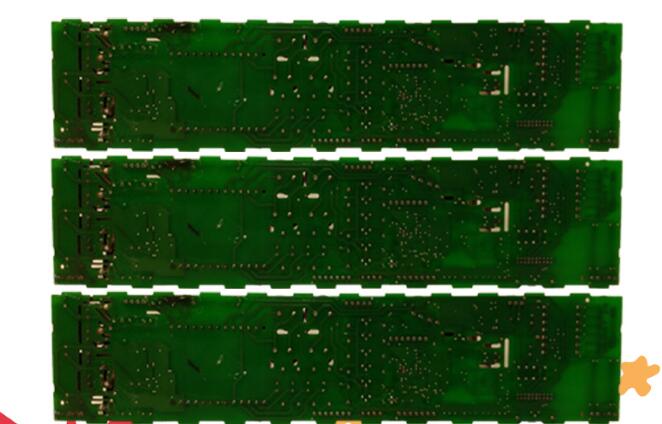

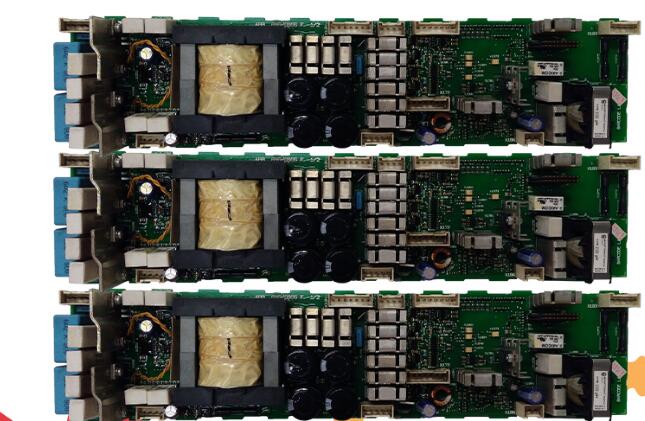

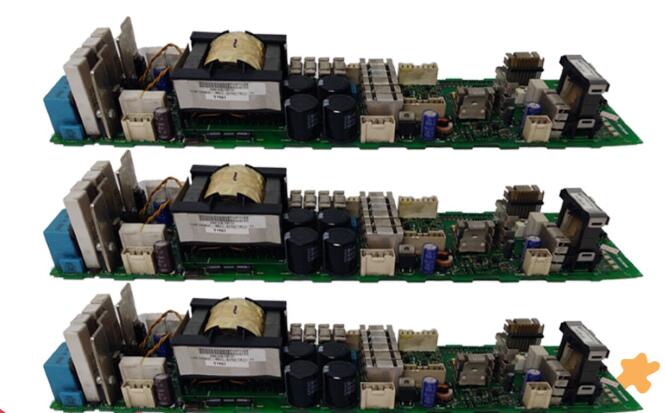

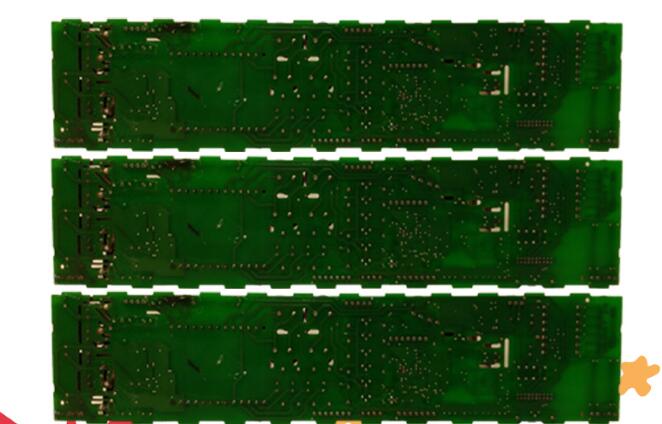

- Product ID:3AUA0000001306

- Place of Origin:USA

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Product Description

3AUA0000001306 Motion Module controller: the key help of industrial motion control

In the complex system of modern industrial automation, efficient and accurate motion control plays a decisive role in improving production efficiency and product quality. 3AUA0000001306 Motion module controller, as a device with advanced technology and excellent performance, is gradually becoming the core component of motion control system in many industrial applications, injecting strong impetus for the development of industrial automation.

Features: Achieve accurate and efficient control

Precise motor speed regulation and stable operation

3AUA0000001306 Motion module controller uses advanced control algorithm, which can control the motor speed very accurately. The speed control accuracy can reach ±0.1%, and smooth acceleration and deceleration can be achieved during the start and stop of the equipment, avoiding the impact of sudden speed change on the equipment, and ensuring the stable and reliable operation of the equipment. For example, in the paper industry, according to the different process stages of paper production, the controller can precisely adjust the motor speed to ensure uniform paper thickness, improve paper quality and production efficiency.

Multi-axis collaborative control capability

The controller has excellent multi-axis synchronous control ability, which can coordinate the motion of multiple motor axes at the same time and realize complex motion trajectory planning. In the field of automatic machining, the machine tool can be milling, drilling and other operations along the preset complex path, and the motion coordination error between the axes can be controlled in a very small range, and the processing accuracy can reach ±0.02mm, which greatly meets the demand for high-precision processing of complex parts and improves production efficiency and product quality.

Intelligent programming and convenient teaching function

In order to facilitate user operation, 3AUA0000001306 is equipped with intelligent programming system and teaching function. The operator can not only input precise motion instructions through traditional programming, but also use the teaching function to manually guide the robot arm to complete specific actions, and the controller automatically records and generates corresponding programs. This convenient operation mode greatly reduces the difficulty of programming, even non-professional programmers can quickly get started, quickly complete the setting of complex motion tasks, and significantly improve production efficiency.

Rich communication interface and protocol support

The controller supports Modbus, Profibus-DP, EtherNet/IP and other industrial communication protocols, and is equipped with RS-485, Ethernet and other communication interfaces to facilitate data interaction with host computer, PLC and other intelligent devices. Through these communication interfaces, operators can monitor the operating status of the equipment in real time, such as motor speed, current, temperature and other parameters, and remotely adjust the operating parameters of the controller according to actual needs, so as to realize the intelligent management of the entire production system and improve the automation level of the production process.

Wide range of uses: suitable for multi-industry applications

Automobile manufacturing industry

In the field of automobile manufacturing, 3AUA0000001306 plays an important role. In the stamping process of auto parts, it can accurately control the movement of the press slider to ensure the dimensional accuracy and surface quality of the stamping parts; In the operation of the welding robot, the precise movement of the robot arm is realized to ensure the accurate position of the welding spot and improve the welding quality and efficiency. In the automobile final assembly line, it is used to control the movement of automated conveying equipment and assembly robots, realize the accurate positioning and assembly of parts, improve the accuracy and consistency of vehicle assembly, and help the efficient and high-quality completion of automobile production.

Electronic manufacturing field

For the electronic manufacturing industry, especially semiconductor chip manufacturing and electronic product assembly, the motion control precision is very high. The controller can be used to control the motion of lithography machine and etcher in chip manufacturing equipment to ensure high precision lithography and etch process in chip manufacturing. In the assembly line of electronic products, it can accurately control the movement of SMT mounters, insert machines and other equipment, achieve rapid and accurate installation and insertion of electronic components, improve the production efficiency and quality of electronic products, and meet the production needs of the electronic manufacturing industry for high precision and high speed.

Logistics and warehousing industry

In the automated logistics storage system, 3AUA0000001306 is used to control the movement of equipment such as stackers and AGVs (automatic guided vehicles). Under its control, the stacker can quickly and accurately store the goods in or out of the shelf, improve the utilization rate of storage space and the efficiency of goods in and out of the warehouse; The AGV drives accurately according to the preset path, realizes the automatic transportation of materials, reduces manual intervention, improves the accuracy and efficiency of logistics operation, and ensures the efficient and stable operation of the logistics warehousing system.

Packaging machinery industry

In the field of packaging machinery, the controller can precisely control the various moving parts of the packaging equipment, such as the feeding mechanism, the sealing mechanism, the cutting mechanism, etc. Through precise speed control and multi-axis collaborative control, to ensure the accurate delivery of packaging materials, tight sealing and product cutting accuracy standards, improve packaging efficiency and quality. Whether it is food packaging, pharmaceutical packaging or daily use packaging, it can meet the needs of different packaging processes and provide reliable motion control solutions for the packaging industry.

Key parameter: Demonstrate superior performance

Rated voltage

The controller is suitable for three-phase AC 380V-480V (±10%) industry standard voltage, can be stable operation in common industrial power supply environment, adapt to different regions and occasions of power supply requirements, to provide a solid guarantee for the stable operation of equipment.

Related recommendations

Contact us

Tel:+86 18059884790

E-mail:plc66@qq.com

E-mail2:plc66@qq.com

Address:whatsapp+86 18059884790

WHATSAPP:+86 18059884790

YOUTUBE:KIMI-YMGK

SKYPE:+86 18059884790

Copyright © Xiamen Xiongba E-Commerce Co., Ltd.