Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: No. 9, 14th Floor, Building 42, Hongshan Lake Road, North Street, Xixiu District, Anshun City, Guizhou Province, China

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

VE3007 EMERSON series controllers

DeltaV™ MX Controller The DeltaV™ MX Controller and the DeltaV I/O subsystem make rapid installation easy. Introduction The MX Controller provides communication and control between the field devices and the other nodes on the control network. Control strategies and system configurations created on earlier DeltaV™ systems can be used with this powerful controller. The MX Controller provides all the features and functions of the MD Plus Controller, with twice the capacity. The control languages executed in the controllers are described in the Control Software Suite product data sheet. Benefits Right-sized controllers The MX controller complements the MQ controllers by providing a larger-capacity controller for those applications that need more control capacity: 2 X the control capacity 2 X user-configurable memory 2 X the DST count Late changes. You can easily upgrade an MQ controller to an MX to handle project scope changes late in the project. The MX installs in the same footprint as the MQ Controllers but delivers twice the performance. Simply replace the MQ with the MX and all existing configuration, documentation and hardware design remain the same — forgiving. Redundant architecture. The MX controller supports 1:1 redundancy for increased availability. Existing MD/MD Plus or MQ controllers can be upgraded online — robust

Increases productivity

Self-addressing. The DeltaV controller is unique in its ability

to automatically identify itself to the DeltaV control network.

When the controller is powered up, it is automatically assigned

a unique address—no dip switches, no configuring—just plug

and play!

Self-locating. A controller’s physical location is easy to find.

LEDs on the face of the controller can be made to flash,

providing a strong visual clue.

Automatic I/O detection. The controller can identify all I/O

interface channels located on the subsystem. As soon as an

I/O interface is plugged in, the controller knows the general

characteristics of the field devices managed by that I/O

interface. This reduces the no value engineering associated

with configuration — easy!

Connect to Electronic Marshalling and Wireless I/O.

Starting in DeltaV v14.3, CHARMs and wireless devices

connected through CHARM I/O Cards (CIOC) and Wireless

I/O Cards (WIOC) can be assigned to the MX controller.

This makes it easier than ever to add I/O to an existing

controller by simply adding a CIOC and/or WIOC to the

DeltaV Area Control Network.

Easy to use

Powerful control. The DeltaV controllers manage all

control activities for the I/O interface channels as well

as all the communication functions to the area control

network. Continuous control function block diagrams,

sequential function charts and phase logic provide powerful

control structures that are further augmented by user-defined

structured text algorithms. Time stamping for alarms and

events is performed in the controller for accurate sequence

of event recording. The controller executes your control

strategy as fast as every 100 ms, and can communicate

up to 4000 exception values per second.

Data protection. All online changes made to control

parameters are automatically stored for later upload into the

engineering database. This way, the system always retains a

complete record of all the data that has been changed online.

Cold restart. This feature provides automatic restart of the

controller in case of a power failure. The restart is completely

autonomous because the entire control strategy is stored in

NVM RAM of the controller for this purpose. Simply set the

restart state of the controller to current conditions.

The MX Controller.

Has the flexibility to meet your needs

Advanced operations. The MX Controller is equipped to handle

the DeltaV Batch option, as well as advanced control functions.

The MX controller uses the same I/O subsystem as the MD

Plus or MQ Controller, but provides more CPU and memory

capacity. It is primarily intended to allow the configuration of a

large unit in a single controller node, where previously two MD

Plus or MQ Controllers were required, due to CPU, memory or

DST constraints, to be consolidated into a single controller.

You can also use advanced control functions such as Neural

and Model Predictive Control on the MX controller.

Data pass-through. The controller is equipped with the

ability to pass smart HART® information from field devices

to any workstation node in the control network. This means

you can take advantage of applications, such as AMS Device

Manager, that enable you to remotely manage the HART

information contained in your HART or FOUNDATION Fieldbus

equipped devices.

Prepares you for the future. As your system grows, you can

expand your software license to increase the number of

device signal tags (DSTs) allocated to the DeltaV controller.

Begin with 50 and expand to 1500 DSTs. Control strategy

complexity and control module scan rates determine overall

controller performance and application size.

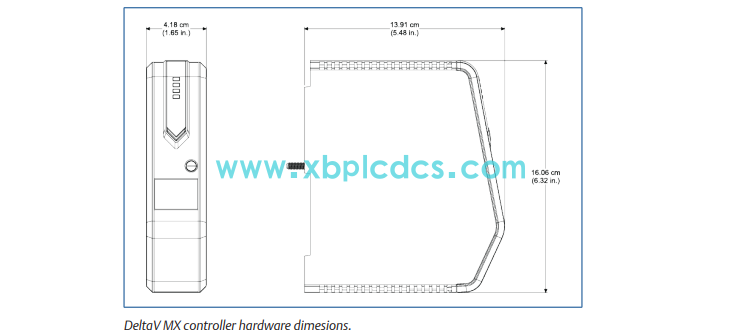

Mounting. This plug-and-play system structure provides modular system growth from a single controller up to 100 controller nodes in a single DeltaV system. Each controller’s I/O subsystem can be expanded online and can be mounted in a Class 1, Div 2 or ATEX Zone 2 environment. Refer to the System Power Supplies and I/O Subsystem Carriers product data sheets for additional information. Designed to support legacy migration Advanced operations. The MX controller provides the DeltaV platform to migrate even the largest of PROVOX SRX controllers, and also supports the PROVOX and RS3 Migration I/O interfaces. The combined CPU capacity and DST count provides sufficient resources for our largest SRX controller configurations to be migrated on a one-for-one basis with DeltaV MX Controllers. The existing PROVOX I/O remains in place using the migration I/O interface to PROVOX with support of up to 1500 real I/O signals. Serial datasets are migrated to DeltaV serial cards and all virtual I/O are no longer required due to the direct module references possible in the DeltaV system. RS3 system migrations to the DeltaV system were fully supported with MD Plus and MQ controllers and the migration I/O interface for RS3. The MX controller can also be used in these projects as necessary.

Certifications The following certifications are available on the MX controller (see actual certificates for exact certifications). CE: EMC- EN 61326-1 FM: FM 3600 FM 3611 CSA: CSA C22.2 No. 213 CSA C22.2 No. 61010-1 ATEX: EN 60079-0 EN 60079-7 IEC Ex: IEC60079-0 IEC60079-7 Marine Certifications: IACS E10 ABS Certificate of Design Assessment DNV Type Approval Certificate Wurldtech: Achilles Communications Certification Level 2

Hazardous Area/Location The MX Controller can be installed and used based on the following Standards (see actual certificates for exact product markings): FM (USA): Installation: Class I, Division 2, Groups A, B, C, D, T4 cFM (Canada): Installation: Class I, Division 2, Groups A, B, C, D, T4 ATEX: II 3G Ex ec IIC T4 Gc IEC Ex: Installation: II 3G Ex ec IIC T4 Gc Regarding the Installation instructions please refer to the following Documents: Class 1 Division 2 Installation Instructions DeltaV M-series (12P1293) Zone 2 Installation Instructions DeltaV M-series (12P2046) Ordering Information Description Model Number MX Controller VE3007 Prerequisites For each controller you will need to select the mounting carrier. Please refer to the M-series I/O Subsystem Carriers product data sheets for details. Each controller requires a dedicated system power supply. Please refer to the M-series System Power Supply product data sheet for details. MX controllers are supported on version 10.3 or later DeltaV systems. Assigning CHARMs and Wireless devices to the MX controller requires DeltaV v14.3 and later software, but is not supported on M-series Controller Interfaces to PROVOX and RS3. Electronic Marshalling requires use of DeltaV Smart Switches between controllers and CIOCs, please refer to Network Considerations for M-series with Electronic Marshalling White Paper.