Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

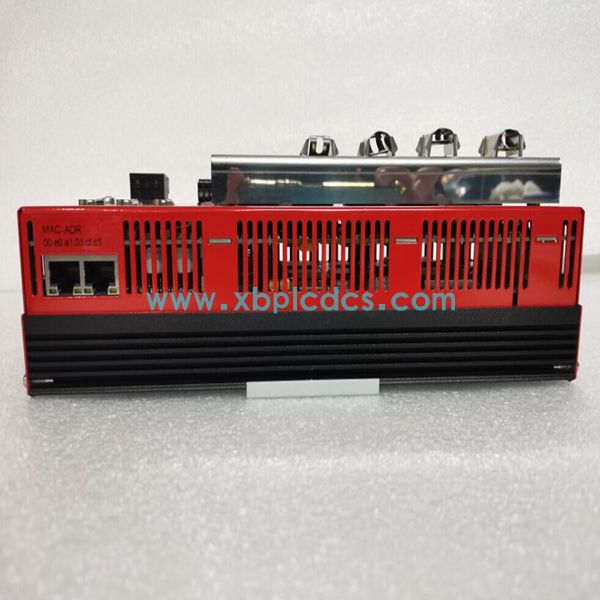

LPA210A HITACHI controller module

The control system of conveying line and assembly line of automobile factory is very complex, it needs to control switch, stop, trap, isolation switch, emergency stop switch, proximity switch, photoelectric switch, transmitter, tensioner, hoist, lifting platform and many other actuator. In the final assembly workshop of Chery's second phase project, two assembly lines were adopted to realize the mixed production of four models. The whole control system consists of the central control room and four remote control stations to form a factory industrial local area network, remote control cabinet PLC through Ethernet to control their own area of production to the central control room of the computer system.

I. System selection and characteristics

On the basis of careful analysis of the products of internationally renowned control system companies, Chery Company decided to use A-B PLC to control the entire production workshop in the second phase of the project according to the experience of automation control technicians in the practical application of products, in view of the good running condition of Rockwell A-B PLC products in the first phase of the project.

A-b PLC enjoys A good reputation in the global industry. Its PLC-5 series, as the flagship product in the A-B brand family, has many functional modules and can realize A variety of complex control systems. In addition, Rockwell's software is numerous and powerful, which can support A wide range of A-B products.

Finally, Chery decided to choose Rockwell's PLC-5 programmable controller, RSLogix 5 programming software, RSNetWork control network configuration software and RSView monitoring software to control the entire production and assembly line of the assembly shop. In addition, the welding conveying line and coating conveying line of Chery's Phase II project also adopted Rockwell's A-B PLC.

The PLC-5/40E CPU features large memory capacity, strong data processing capability, and powerful network functions. With an Ethernet network port, the PLC-5/40E CPU does not require additional Ethernet communication modules. PLC-5/40E CPU uses the key switch to change the operating mode of the processor: in the running mode, the user cannot create or delete program files, create or delete data files, or change the operating mode through programming software; In programming mode, software programming cannot change the mode of operation; Change between remote programming, remote testing and remote running modes through programming software.

RSLogix 5 programming software has reliable communication ability, powerful programming function and excellent diagnostic ability, monitoring ability, operation control function. Using RSLogix 5 ladder logic programming software can optimize system performance, save project development time, improve productivity.

Upper computer monitoring software RSView32 is Rockwell Automation company launched the configuration software platform, its characteristics are easy to use, can construct a flexible interface and powerful functions, can develop a strong combination of pictures. Using the upper computer monitoring software RSView32, sitting in the central control room can be at a glance to the site production, to achieve monitoring production.

www.xbplcdcs.com

Tel:+86 18059884790

E-mail:plc66@qq.com

E-mail2:+86 18059884790

Address:whatsapp+86 18059884790

Copyright © Xiamen Xiongba E-Commerce Co., Ltd.