Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

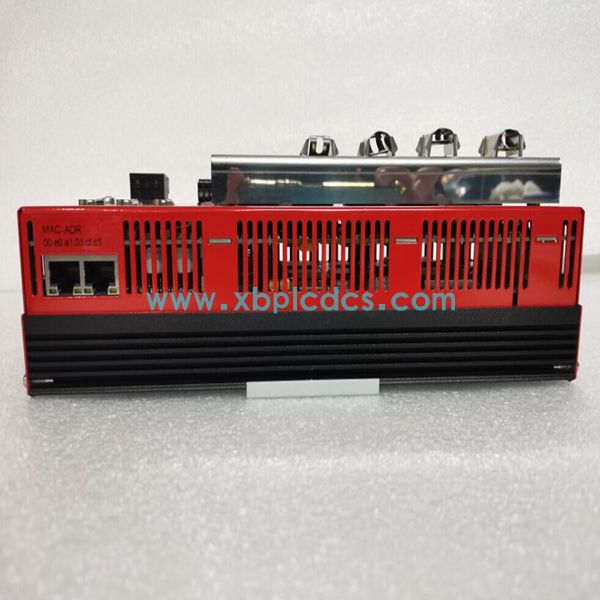

LYD105A HITACHI control module

Central heating is generally used in winter in north China. The thermal power plant sends the hot water to the residential area and the heat exchange station in the enterprise through the urban high temperature heating pipeline. In the heat exchange station, the hot water in the high temperature pipe (hereinafter referred to as the primary network) and the hot water in the incoming room radiator (hereinafter referred to as the secondary network) exchange heat through the heat exchanger. After heat exchange, hot water flows into each room in the secondary network.

In the above process, the heating dispatching department needs to centrally monitor the temperature, pressure, flow rate, liquid level and other parameters in the heat exchange stations scattered in different geographical locations in real time to control the operation of each equipment in the heat exchange stations. At the same time, according to the operation parameters of each heat exchange station monitored from the site, the operation condition of the thermal power plant is adjusted to ensure the stable operation of the whole heating in winter.

Therefore, it is very important to collect the field parameters of each heat exchange station and communicate the real-time data between the control room and each heat exchange station. Here, the author puts forward an advanced wireless monitoring scheme: HOLLiAS-PLC G5 of Beijing Hollysys System Engineering Co., Ltd. was installed in each heat exchange station to complete site parameter collection and equipment control. HOLLiAS-PLC G5 on site established reliable and stable communication with control computer of dispatching center through GPRS network, and all heat exchange stations on site could be monitored and controlled in the dispatching center.

This scheme has been applied in the heating monitoring system of Shenyang Huanggu Thermoelectric Co., LTD. The following is a detailed description.

2 System Overview

As shown in Figure 1, the heating monitoring system of Shenyang Huanggu Thermoelectric Co., Ltd. consists of three parts: HOLLiAS-PLC G5 control part of the on-site heat exchange station, GPRS data transmission part and the data center of the control room. The HOLLiAS-PLC G5 CP240 RS-232 module is used to complete data interaction with GPRS DTU. PLC periodically sends data to GPRS DTU, and PLC receives data from DTU in real time to complete the corresponding control function. GPRS DTU immediately forwards data sent by PLC to the data center. According to the actual situation of the heat exchange station, the PLC of the heat exchange station sends 140 bytes of frame format data to DTU each time, including all analog and switching quantities.

(1) The on-site heat exchange station HOLLiAS-PLC G5 collects the process parameters in real time and sends the data to GPRS DTU communication module through RS-232 serial communication module; At the same time, it can also receive instructions from the dispatch center through the communication module.

(2) The GPRS data transmission part enters the fixed IP address of the data center in advance when configuring the GPRS DTU communication module. After receiving the data from HOLLiAS-PLC G5, the GPRS DTU communication module sends the data to the host with the IP address set previously (namely, the data center router). The process of GPRS DTU sending data is as follows: the data is sent to China Mobile GPRS network, and then through the Internet, and finally received in the data center through ADSL. The data center router receives the data of each heat transfer station and forwards it to the data server.

www.xbplcdcs.com