Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

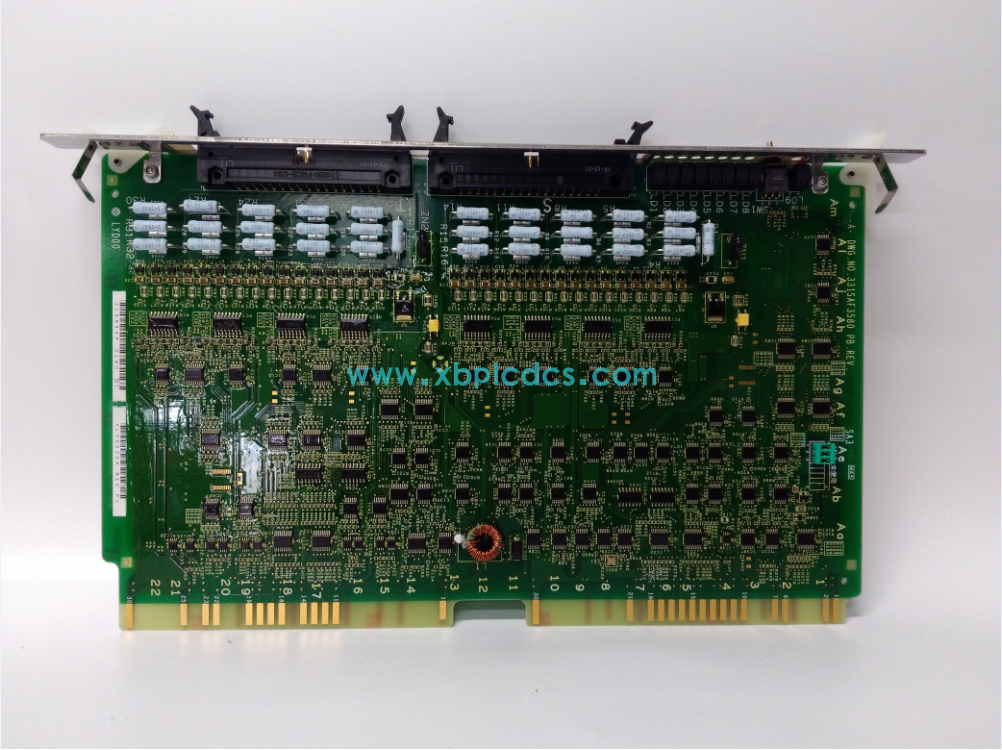

LYA010A HITACHI controller module

CS31 communication bus

CS31 field bus from 1989 to now, has been playing the role of a link between the past and the future. Through this bus, the multiple sets of systems before and after the organic link together. The CS31 bus is easy to set up and simple to communicate. The connection of the bus only needs to be realized through three wiring terminals, saving the additional connection cost required by other buses. The COM1 port of AC500 control system integrates the functions of CS31 master station.

Network structure and communication medium

CS31 bus is a point-to-multipoint RS485 serial communication. Each communication system consists of a master station and a maximum of 31 slave stations. The communication distance is 500 meters without the relay, and the maximum can reach 2000 meters with the relay. The bus comes with self-diagnosis. The communication medium is: shielded twisted pair.

AC500ControlBuilder programming

AC500ControlBuilder programming is a set of engineering tools for all series of AC500CPU programming, this programming software conforms to the international standard IEC61131-3, can support five different programming languages. The software can complete the AC500 system setup, including all bus interfaces, but also has full self-diagnosis, alarm handling, visual debugging tools and open data interface.

In line with IEC61131-3 standard programming

This set of programming software in addition to excellent performance, friendly interface for all hardware in the system related programming, testing, debugging to achieve a variety of automation applications also provides the following functions:

Five standard programming languages:

- Function Block (FBD)

- Statement table (IL)

- Ladder diagram (LD)

- Structured text (ST)

- Sequential Control Diagram (SFC)

Continuous Function Diagram (CFC)

● Debugging tools:

- Single step

- Single cycle

- Break point

Offline simulation function

AC500ControlBuilder can simulate and debug user programs without connecting to PLC hardware, including related manual functions. The debugging program is then downloaded to the CPU control system for use.

Variable tracking function

Online real-time monitoring of all process variables over time.

Recipe management and monitoring lists

You can have a preset set of associated values for a set of variables that you can call when debugging. This feature is useful for controlling the timing of parameters.

Visual debugging tools

In this set of programming software, the PLC variables through the change of color, object movement, bitmap, a variety of histogram or direct display of values displayed on the software, in order to facilitate the user program debugging, as well as alarm and event management, and provide network multimedia (ActiveX) function.

Set the communication interface

Through this software can realize Profibus-DP, CANopen, DeviceNet, Ethernet, Modbus and CS31 bus Settings.

Open data interface

DDE and OPC can be used for external data exchange.

programming

It can be programmed over Ethernet and ARCNET network.

Engineering interface

The programming software has access to an external project database to manage one or more automated projects.