Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: whatsapp+86 18059884790

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New / Used

- Shipping method: Courier delivery

- Contact person: Linda

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

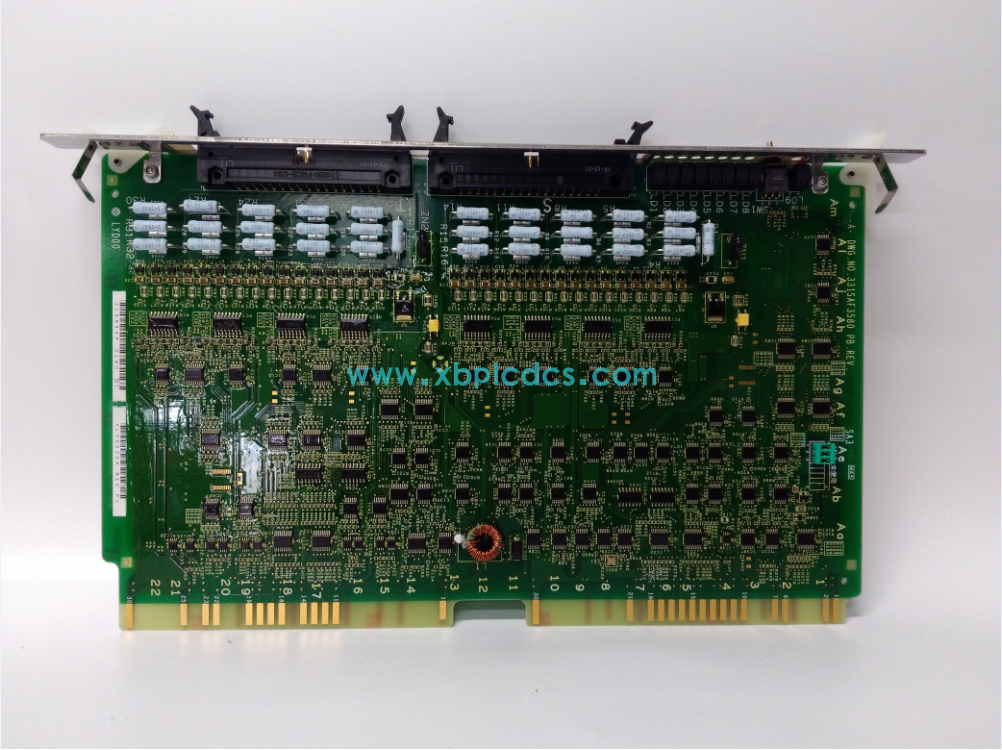

LPU100H HITACHI controller module

LPU100H HITACHI controller module

LPU100H HITACHI controller module

Software Configuration

a) Upper computer monitoring software

The upper monitoring software of this system chooses iFix3.5 of Intellution as the development platform. Using the variable archive editor and Crystal report designer of this software, it is convenient to generate user files and reports for running user process data. The ODBC function is used to record the alarm of all equipment and the operation of personnel, and to notify the operator through the sound, so that the operator can deal with it immediately, and to create favorable conditions for the analysis of the cause of the accident in the future.

b) PLC control software

PLC control software uses ROCKWELL company's RSLogix 5000 programming software, RS-LINX communication driver software and RSNetWorx configuration software as programming debugging software development platform. It can use the ladder diagram programming method and the IEC programming method, which gives the programmer more freedom. The advantage of this software is that there is a powerful functional block system, for different functions have a functional block corresponding to it, programming is simple and flexible.

5. Control of system

When starting automatically, start the equipment in the order of reverse coal flow direction; Automatic stop, according to the direction of coal flow delay stop equipment; In case of an accident trip of an equipment, reverse coal flow trip starts from the faulty equipment (iron remover, electronic belt scale and sampler do not participate in trip). And the system allows multiple processes in operation, but not allowed to operate two or more processes at the same time to start or stop. When two processes are running, if a device in one of the processes fails and the process hops, the other process cannot be affected. Please refer to the "System General Appearance" diagram for the location and process sequence of the specific equipment:

Before the system starts automatically, you need to select a process. If both processes select a device at the same time, an alarm is raised.

Process selection needs to be carried out through the upper computer process selection screen. In this coal transmission program control project, we have set a total of 8 process selection sub-screens, see the "process selection" chart:

Each process selection screen is set with a Select all band key and a Select All Band key. Once the Select All band key is pressed, all bands in this process will turn into a dark blue color, indicating that they are selected.

In addition, each belt itself has a selection key, which can be used to remove the faulty belt from the process and choose the other side of the belt to replace it, so that the equipment on side A and B can be used across. After the device is selected, press the Confirm button to know whether the selected path is correct. If the path is correct, you can proceed to the next step. Otherwise, you need to select the path again. When the process is finished, use the process clean key to clear the process to avoid errors when using the same equipment in another process. See the selection chart of "Process from Coal Plant No. 1 to Coal Bunker" :

If the selected process is a valid process, the voice prompts you to perform the next Pre-Start operation. After this operation is issued, the three-way baffle is hit to the selected path, and the roller screen (if in the process) and the coal crusher (if in the process) run. If the baffle is normally started in place during the 30-second pre-start process, a voice prompt of "Allow to Start" is issued. In this case, you can start the process. After selecting "Cheng start", the equipment along the line starts all the equipment to the coal source by delay from the end belt conveyor against the direction of coal flow according to the selected process. When the coal loading is finished, the "stop" operation is carried out immediately. When multiple processes are running at the same time, the coal source should be selected first and then the process stop operation should be carried out. According to the selected process, the process stop operation starts from the coal source equipment and follows the direction of the coal flow one by one and stops all the equipment in the predetermined delay time sequence until the last one. The delay time is to ensure that each operating equipment will not stop until the coal is gone.

During automatic operation, when a certain equipment fails or has an accident, such as belt tearing, rope pulling, heavy run deviation, skid or coal blocking lasting more than 2 seconds, stop the belt immediately and jump all equipment against the direction of coal flow. However, the downstream devices at the fault point remain in the original working state. After the fault is rectified, perform the Reset operation and then the Pre-start operation again to start the device upstream from the fault point. Also, when the fault is not removed, the operation of "stop process" can be carried out, starting from the downstream of the fault point and along the coal flow direction, to stop each equipment one by one according to the predetermined delay time sequence until the end. The coal crusher and roller screen will stop 30 seconds after the accident extension. When pressing the "emergency stop" button (there is this switch on both the operating platform and the upper computer), the full-line operation equipment will stop immediately, and the coal crusher and roller screen will stop after a delay of 30 seconds.

Tel:+86 18059884790

E-mail:plc66@qq.com

E-mail2:+86 18059884790

Address:whatsapp+86 18059884790

Copyright © Xiamen Xiongba E-Commerce Co., Ltd.